ATB®

ATB® es la abreviatura de Sistema de Cepillos de Tecnología avanzada y forma nuestra gama de productos de cepillos para el desbarbado automatizado directamente después del proceso de mecanizado.

ATB® - High-tech brushes for automated deburring.

ATB® brushes are precision tools that are largely responsible for the quality of the end products. They can be matched component-oriented to almost any material to be processed.

Our ATB® brushes are available with a wide range of abrasive bristles and wire trim in different grit sizes and filament/wire diameters.

ATB® brushes are designed for direct adaptation to tool holders, which means that they can be used in machining centres, CNC lathes & milling machines, robot cells, etc.

The brushes are used downstream of the machining process and can be used with cooling lubricants, emulsions or water without any problems.

This means that the machined workpieces can be deburred and finished directly, reliably and reproducibly on the machine without reclamping.

Before/after comparison.

Before machining - clear burr formation on the edge. Milling grooves on the surface.

After machining - burrs were reliably removed and the edges rounded. The surface has an even, brushed look.

Advantages and

Application examples.

ATB® brushes have a 4 x higher fill density than the disc brushes produced in the conventional process (punched). As a result, the service life of the brushes is increased many times over, with higher throughput speeds and better and more efficient deburring results.

- Minimal process costs

- Firmly encapsulated abrasive bristles

- Extremely dense fill surface

- Enormously long tool life

- High dimensional stability and concentricity

- Use of cooling lubricant, emulsions and water possible

- Plane fill surface

- Numerous, different fill materials e.g. abrasive bristles, wire materials, mixed fill material

- No reclamping of the workpiece after machining

Due to shorter machining times and very uniform edge rounding, our ATB® brushes are particularly suitable for deburring:

- Milled and turned parts

- Ground parts

- Sintered parts

- Stamped, nippled and pressed parts

- Pneumatic and hydraulic parts

- Engine components, e.g. cylinder head, cylinder block etc.

- Die-cast parts

- Valve plates

- Flat ground parts

- Toothed components

- Contact and sealing surfaces

- Finishing

Osborn

ATB® portfolio.

Tool holders & adaptability.

ATB® brushes are compatible with the following tool holders for direct adaptability for use in automated machining stations:

ATB®-Disc brushes

- Shell mill adaptors DIN 69882-3 / Universal arbors DIN 69882-2

- Planet head holder

- With Osborn clamping sets, other holders are possible such as Weldon holders or similar.

- Toolholders with HSK-taper shank DIN 69893

- ISO Taper-toolholders SK nach DIN 69871

- Holders for straight shank tools DIN 69882-4 (Weldon DIN 1835 B) etc.

ATB®-Wheel brushes

- Shell mill adaptors DIN 69882-3 / Universal arbors DIN 69882-2

- Through hole with and without keyway

- With Osborn clamping sets (shank holders)

- Toolholders with HSK-taper shank DIN 69893

- ISO Taper-toolholders SK nach DIN 69871

ATB®-End brushes

- shank holders

- Toolholders with HSK-taper shank DIN 69893

- ISO Taper-toolholders SK nach DIN 69871

- Holders for straight shank tools DIN 69882-4 (Weldon DIN 1835 B) etc.

Trim patterns & designs.

In order to achieve the best possible deburring and finishing results, different fill patterns and designs are required. Depending on the available product families of ATB® brushes, we offer the following fill types, among others:

ATB® disc brush

- full fill (max. fill density)

- partial fill (segmented)

- turboshape

- ring fill

- tapered/angled fill (under angle)

- spotted version

ATB® wheel brush

- full fill (max. fill density)

- partial fill (segmented)

ATB® End Brush

- full fill (max. fill density)

Determined by the material to be processed and the workpiece geometry, ATB® brushes can be equipped with various fill materials, from wire fill to abrasive bristles to mixed fill.

Technical feasibility & standard configurations.

In order to make the best possible use of the advantages of our ATB® product line, it is often necessary to exchange ideas with our product professionals. Often, application-specific brushing tools are worked out for the customer, which is developed taking into account the entire machining process.

We offer the following standard configurations (dimensions) for the three ATB® product families:

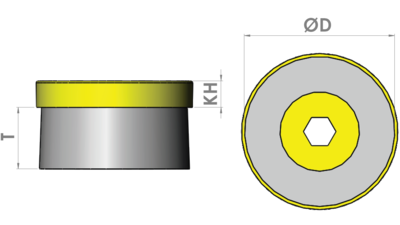

ATB® Disc brush

- Outer-Ø D: Ø40 to Ø250 mm

- Trim height T: 35 mm

- Body height KH: 13 mm

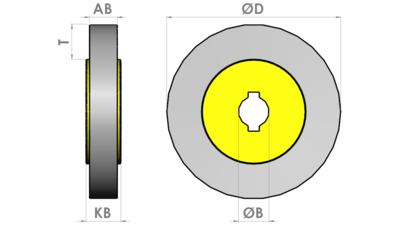

ATB® Wheel Brush

- Outer-Ø D: Ø100 to Ø355 mm

- Working width AB: 6 to 36 mm

- Body width KB: 10 to 40 mm

- Mounting hole ØB: 16 to 134 mm with and without keyways

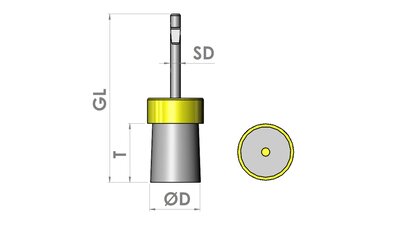

ATB® End Brush

- Outer-Ø D: Ø16 to Ø40 mm

- Trim height T: 25 to 30 mm

- Shaft diameter: 6-8 mm

- Total length SL: 85 to 176 mm

ATB®

Productos.

Cepillo de desbarbado interno de servicio pesado ATB™

Los cepillos de desbarbado internos de alta resistencia Osborn ATB™ presentan un mayor contenido de filamentos y están diseñados específicamente para abordar eficientemente las tareas más difíciles. Los filamentos flexibles de nylon crimpados cuentan con un abrasivo duradero de Carburo de Silicio y se fabrican con una forma helicoidal, lo que proporciona un rendimiento óptimo en ambas direcciones de rotación con una excelente conformabilidad de la pieza.

Cepillo abrasivo de diamante para ruedas ATB™

Los cepillos de rueda están diseñados para proporcionar resultados uniformes y repetibles, ofreciendo un rendimiento superior en una variedad de aplicaciones de pulido, desbarbado y afilado de bordes. Estos cepillos están diseñados para un afilado de bordes óptimo de materiales ultraduros como CBN, cerámicas, diamantes y vidrio, sin sacrificar la vida útil del cepillo. Los ATB™ Diamond Superabrasives de Osborn reducen los costos del proceso y crean un entorno de producción más limpio y eficiente al minimizar o eliminar la operación de limpieza secundaria.

Brida ATB Uni-Lok®

Enhance the aggressiveness of Osborn's ATB™ Composite brushes with ATB Uni-Lok® Bridles. Sold in packs of three, these Bridles are specifically designed to reduce the flare of filaments, increasing the rigidity of the brush for heavy-duty applications. Please note that these Bridles are not intended for use on ATB™ turbo discs.

Cepillo de copa en miniatura ATB™

Los cepillos de copa miniatura Osborn ATB™, que cuentan con filamentos de nylon con una forma de expansión y la opción de incluir abrasivos incrustados, ofrecen una excelente condicionamiento de superficies, limpieza y pulido. Los diseños de cepillos de copa brindan un rendimiento uniforme en áreas más amplias.

Cepillo de copa ATB™ con mango

Construido con un vástago de ¼" permanentemente adherido y un menor ensanchamiento para aumentar la rigidez, el cepillo de copa con vástago ATB™ de Osborn ofrece una acción de cepillado agresiva en superficies irregulares o planas. El cepillo cuenta con filamentos redondos de nylon abrasivo de alta calidad, recortados en forma de copa, para proporcionar uniformidad en múltiples direcciones. Diseñado y probado para una longevidad máxima.