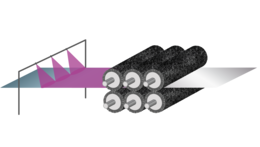

Brush Rolls

Application.

Depending on the type and degree of contamination of the primary material and the strip cleanliness required for the process step, different requirements are placed on the brush. While optimum degreasing and micro-cleaning can be achieved with non-abrasive multifilaments, abrasive filaments are ideal for removing strongly adhering material residues from the previous rolling process.

Osborn rolling brushes are therefore customised for each individual case. Multifilaments and special monofilaments with or without abrasive content can be used as single filaments or mixed filaments.

Surface activation is an important step in the production of roll cladding, as well as in the coating or finishing of steel strip, tinplate, electrical steel and other materials. During roll cladding, core and if necessary overlay strips or plates must first be cleaned of oil, grease, dirt, carbon particles and oxides in alkaline cleaners or acidic pickling baths using roller brushes. In the next process step, the surface is given a defined roughness using abrasive and wire brushes. A similar process takes place in continuous coil coating. In both cases, surface activation ensures optimum adhesion for the subsequent roll cladding or organic or metallic coating.

The individual requirements for the brush can vary greatly depending on the flatness, hardness and surface of the starting material as well as the type of subsequent coating or plating.

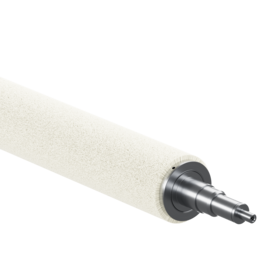

Standard Brush Rolls

Cleaning, descaling, degreasing and scratching in Metal Sheets and Strip Processing Lines

- Price Competitive and good Cleaning and Life Performance

- Flexible brush system–based on customer‘s and application requests

- Either as customer or as factory brush system possible

- Standardized brush materials

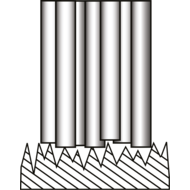

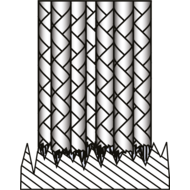

Standard Brush Rolls (Mono-Filament)

- Imprecise brushing

- Low cleaning performance

- Short life-time

- Low contact density

- Irregular brushing

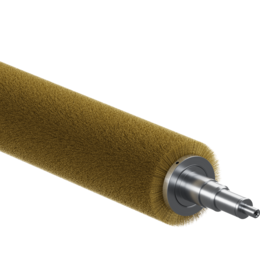

HDL Premium Brush Rolls

Cleaning, descaling and strip surface finishing for all Metal Sheets and Strip Processing Lines

- Very precise brushing control

- High cleaning performance deep in the strip surface roughness

- Very long life-time

- High-contact density

- Uniform surface finishing

- Very uniform brush wearing

- Reducing maintenance costs

Osborn HDL (Multi-Filament)

- Very precise brushing

- High cleaning performance

- Long life-time

- High contact density

- Even brushing

General Information.

Degreasing, Washing and Cleaning

| Metallurgic Field | Process Line | Description of Apllication |

|---|---|---|

| Steel |

|

|

| Stainless steel |

|

|

| Aluminium |

|

|

| Non ferrous |

|

Activation of Strip Surface

| Metallurgic Field | Process Line | Description of Application |

|---|---|---|

| Steel |

|

|

| Aluminum |

|

|

| Non ferrous |

|

Strip Polishing and Finishing

| Metallurgic Field | Process Line | Description of Application |

|---|---|---|

| Steel |

|

|

Scale Removal

| Metallurgic Field | Process Line | Description of Application |

|---|---|---|

| Carbon steel |

|

|

| Stainless steel |

|

|

| Non ferrous |

|

|

Brush Systems for Self-Assembly by the Customer.

We also offer solutions for customers who want to restore and maintain their brushes in-house – roller systems for self-assembly.

Our product and service range includes sections with fully automatic, internally welded spiral constructions, disc systems, as well as versions mounted on disposable tube bodies or older designs with single discs or loose spirals. To adapt these individually to existing shaft constructions, single-use adapters are added if required. This enables us to supply the right brush section for almost any customer shaft – unmatched by any other manufacturer worldwide. At the same time, all common filaments, wires, or natural bristles can be used and customized in trim length and density – from light to standard to extremely dense. We also provide suitable equipment for easy follow-up trimming of the roller on a lathe.

With our modern shaft constructions it is possible to avoid balancing the shafts. Precision manufactured inner diameters in narrow tolerance ranges ensure that the individual sections sit optimally on the shaft and prevent vibrations when running. Intelligent and well-engineered roll constructions without complicated clamping systems make the exchange of brush coverings fast and simple. Osborn brush segments are trimmed in sets. Each individual segment is labelled and marked in accordance with the assembly instructions. This ensures simple and complete assembly without diameter variations.

Helimaster.

Application.

Osborn’s Helimaster brush rolls are perfect for cleaning work and back-up rolls in wet or dry operated rolling and skin-pass mills. They have been fitted to technological developments worldwide for decades, both in online lines integrated in strip lines and stand-alone off-line rolling stands.

The rollers can work sporadically or continuously when designed as a wire or an abrasive brush. Each brush is neutrally ground without sticking-out wire or filament tips. This means that it gets either a cylindrical camber ground or, for offsetting the computed roll deflection, a positive camber ground.

The brush roller itself is only part of the solution. This technologically demanding application can only be optimally implemented with a precise matching of the brush tool to operational and process parameters. The reproducibility of the specified corrosiveness and brush effect as well as constant tool performance play a crucial role from the first point of use to the exchanging of the roller.

For the cleaning of deflector, shape control or thickness measurement rolls, special wear-resistant non-abrasive plastic filaments are used. They ensure an equally thorough removal of solids and liquid materials without damaging the roll surface or altering the roughness.

At the same time, the filament type and bristle diameter are dependent on the surface hardness and the degree of pollution of the roll that requires cleaning.

The individually adapted camber ground of the brush roller body is one of the most important prerequisites for guaranteeing uniform brushing across the entire width of the roll. Depending on the construction of the working or back-up rollers to be brushed and the calculation of the optimum crown, convex or concave contours are ground. Osborn, of course, also grinds brush rollers with a CVC contour on CVC technology.

Cylindrical

CVC

Convex

Roll Coating Control and Cleaning in Hot and Cold Rolling Mills Roll

- Very precise brushing control

- Very high density brush rolls

- Very long life-time

- Flexible ground brush surface contours – (convex, CVC, cylindric)

- Customized brush material (considering customer‘s set up and back-up rolls)

- Long ground Helimaster brush rolls possible – length 7000 mm

Roll Cleaning and Polishing

| Metallurgic Field | Process Line | Description of Application |

|---|---|---|

| Carbon steel |

|

Removal of oxides, dirt and rolling residuals |

| Stainless steel |

|

|

| Aluminum |

|

Roll Coating Control

| Metallurgic Field | Process Line | Description of Application |

|---|---|---|

| Aluminum |

|

Control of the oxide layer and removal of oxides |

| Non ferrous |

|

Brushes with

Bessemer Wire.

Our Bessemer roller brushes are designed with exceptionally long filaments, providing outstanding flexibility and an ultra-soft touch. This makes them ideal for delicate surfaces or applications where gentle, consistent contact is essential.

A combination of Bessemer wire roller brushes and polishing emulsions is used for the removal of oxide layers and for the polishing of cold rolled uncoated strips after annealing re-crystallisation. Both components come from Osborn and are specifically matched to the individual surface requirements.

The osborn polishing emulsion is initially applied to the strip surface by a pressurized spraying system or alternatively in an immersion bath or similar.

With Bessemer wire measuring from 0.08mm to 0.20mm, filled brush rollers serves as a carrier of the polishing compound in the subsequent polishing process. Polishing is normally done in two or more stations.

To ensure maximum product compatibility and to achieve outstanding polishing results, we offer high-quality polishing emulsions which are developed and manufactured in-house and precisely matched to your application.

We offer our emulsions in various types of packaging. From large rental containers for large-scale use to single cardboard packs for smaller quantities. So you have the right solution for every application.