Brush Furnace Rolls

Application.

The tempering of hot mill plates made of hardening aluminium alloys, serves the purpose of attaining higher strength and strain values along with a good level of corrosion resistance. This is required, for example, for construction parts in aircrafts.

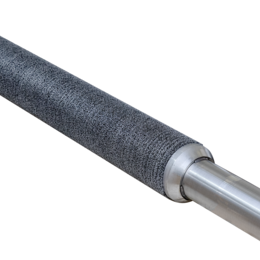

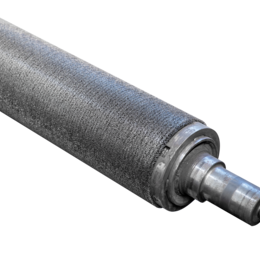

The careful transportation of these aluminium plates in horizontal roll hearth furnaces takes place as a batch or continuous process at temperatures of up to 600°C on brush transportation rolls. In the process, plates with thicknesses of up to 400mm, lengths of 20 metres and weights of over 10 tonnes do not present a problem for us. Tolerances have been continually reduced and product features optimised, so that now more than ever, the brush roller is an integral and technologically superior component in the overall design of the line.

After the rolls have been manufactured, the later course of the sheet is accurately simulated in advance in our factory. For roll assemblies in new furnace lines, this allows Osborn to guarantee an optimum course of the sheet within tight tolerances even when starting up the run.

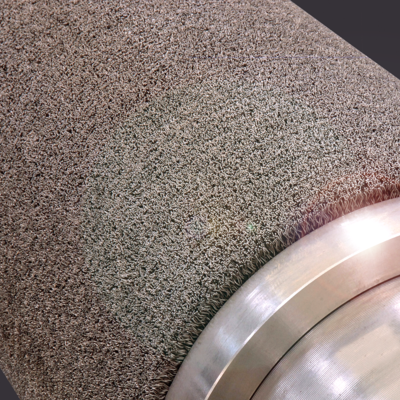

Roll coverings made from extremely dense stainless steel wires in special alloys and resistant to high temperatures provide specific product features and strong advantages compared to uncoated transportation shafts or furnace rollers with ceramic coatings. These can be used in different horizontal heat treatment lines for strips of steel, stainless steel or non-ferrous metals.

Solutions.

Brush Furnace Rolls for Aluminium

Aluminum Plates Heat Treatment Furnaces

- No pick up

- Controlled tracking

- Longer lifetime

- No marking

- Reduced noise

- Optimal thermal conduction between rolls and plates

Brush Furnace Rolls for Carbon Steel

Carbon Steel Annealing Furnaces (CAL and CGL) and tube production

- No pick up or indentation

- Higher wear resistance compared to ceramic

- No ceramic particles detached

- Improved zinc adhesion

Transport Rolls for Heavy Plates Outside the Furnace

- No pick up or indentation

- Gentle transport without damage to the plate bottom side

- Significant noise reduction

Brush Furnace Rolls for Electrical Steel

Electrical Steel Annealing Furnaces for GO or NGO (ACL and DCL)

- No pick up or indentation

- Higher wear resistance compared to ceramic or graphite

- Extremely longer life compared to ceramic discs

- No cover oxidation

- No ceramic or graphite particles detached

- Improved shaft deflection

- Improved magnetic and isolation properties for electrical steels

Brush Furnace Rolls for Stainless Steel

Stainless Steel Annealing Furnaces (CAPL, HAPL and BAL)

- No pick up or indentation

- High wear resistance compared to ceramic or graphite

- No cover oxidation

General Information.

Transport Roll Systems for Horizontal Heat Treatment Furnaces and Other Roll Applications

| Metallurgic Field | Description of Application |

|---|---|

| Carbon steel |

|

| Stainless steel | |

| Non ferrous | |

| Aluminum |

|

Properties and Advantages

- Temperature resistance of up to approx. 1250°C

- Shaft construction as dry roll or internally cooled roll

- Extremely dense and accurate neutrally ground surface of the rolls

- Significantly better heat transfer characteristics of the tips of the wires in comparison to full metal surfaces

- No scale pick up (formation of spots) on account of the absorption properties of the exposed brush surface

- Reduced maintenance

- Particularly careful transportation of the plates and reduction of damage to the surface

- Very low wear to the rolls with significantly longer lifespan than ceramic coatings or other roll coatings

- Significant noise reduction of <30% during sheet metal transport

No Pick Up.

Pick-up can form during transport in high-temperature areas. Material builds up on the roller surface or sticks to it, which significantly disrupts the smooth transport process. Pick-up causes increased wear and maintenance costs and also affects product quality.

Conventional Brush:

Osborn Brush: