Non-Woven Rolls

Application.

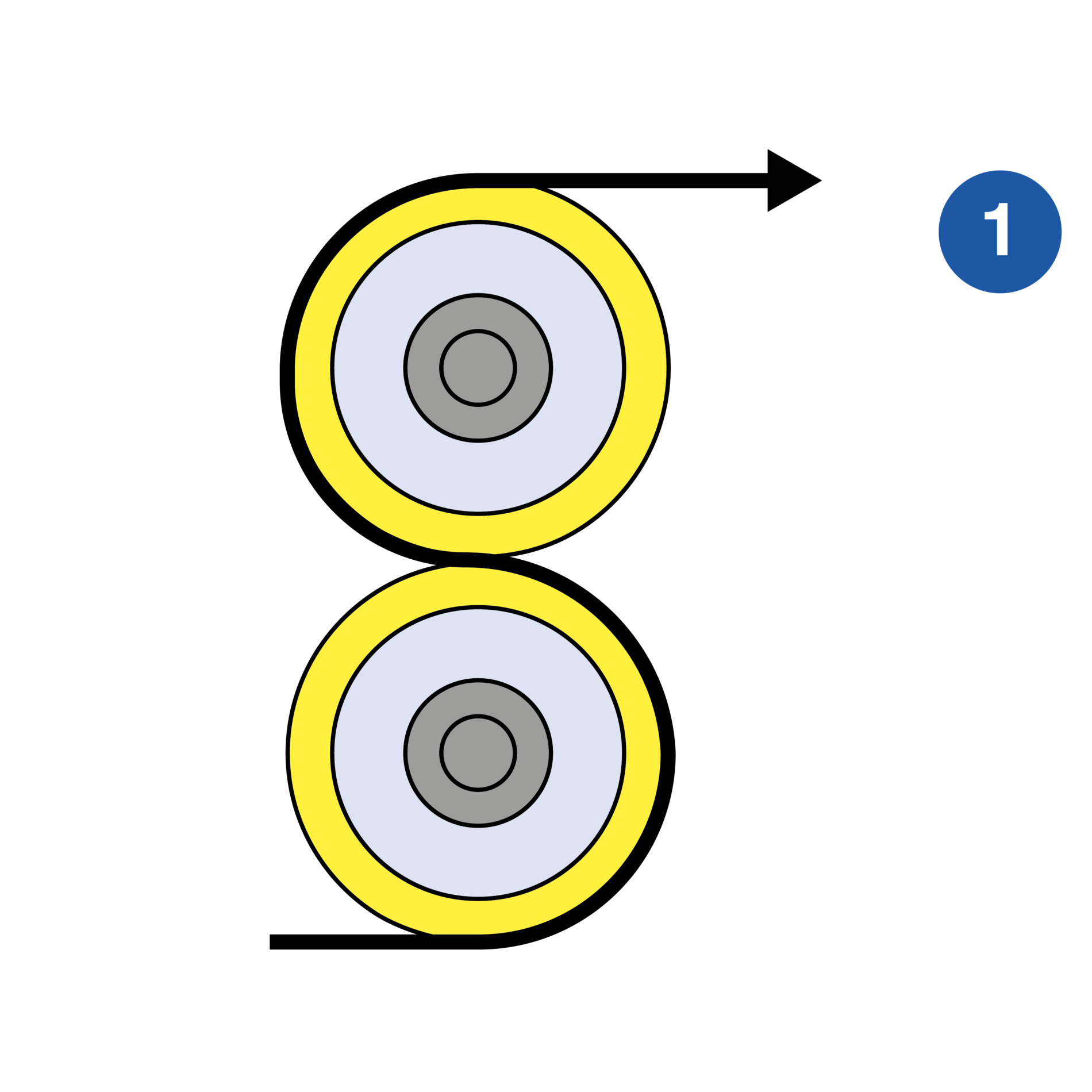

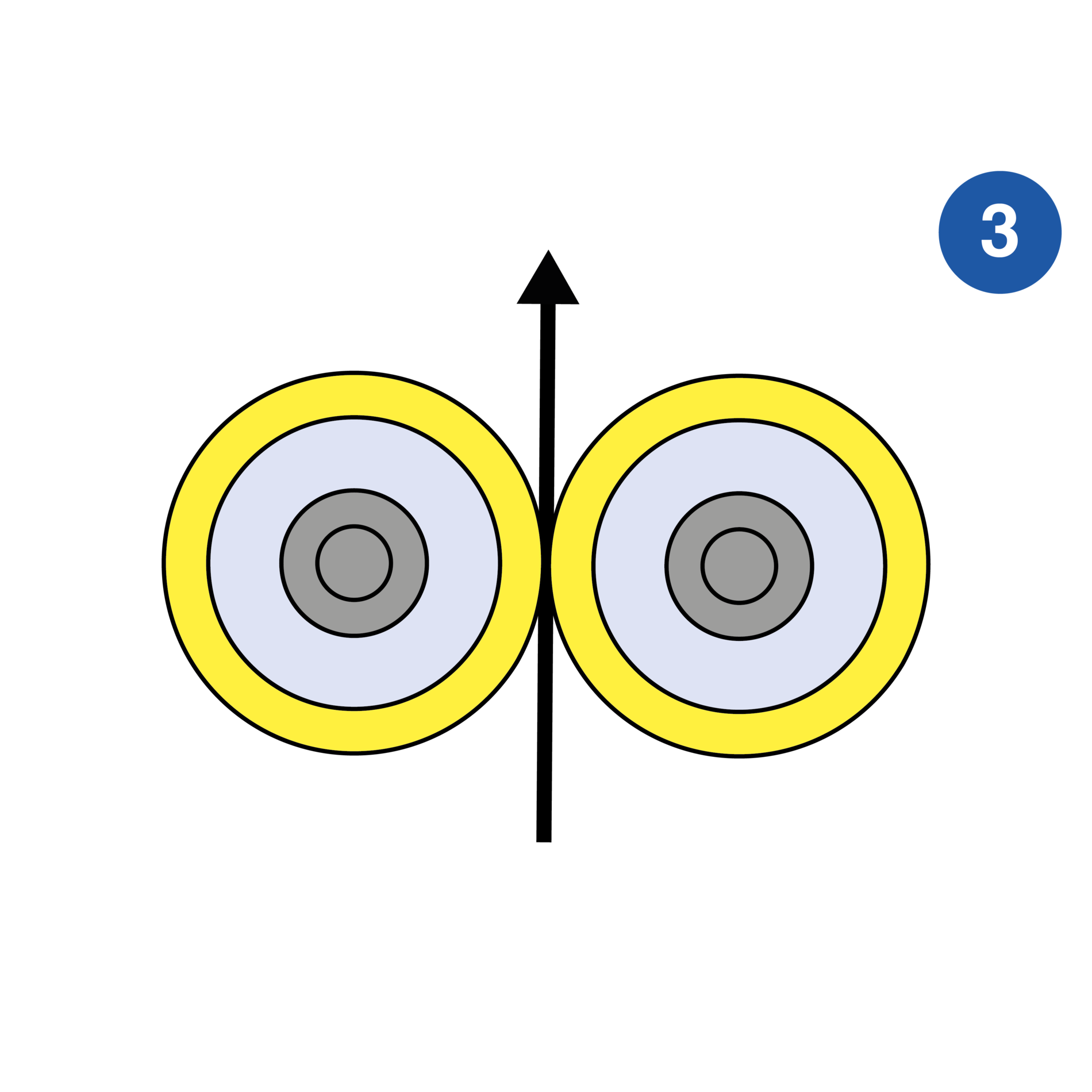

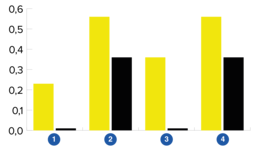

1./4. Non-woven rollers offer particular advantages as bridle, tension, steering or deflector rolls. In dry and especially wet conditions, non-woven fabric has an excellent and consistent friction coefficient, both on oil and aqueous media. The friction coefficients of rubber or polyurethane coated rollers, on the other hand, are very low, which can easily lead to aquaplaning on non-driven rollers. Aquaplaning describes the floating of the rollers, resulting in strip slippage and the scratches and surface damage caused by this. Non-woven coatings adhere excellently to strip surfaces. As a result, significantly higher tensile forces can be realised, belts can be kept taut and controlled much more precisely.

2./3. These material properties also speak in favour of non-woven rollers when used as brake or tension rolls. Due to the strong and consistent adhesion between the roller and strip surfaces, strips can be pulled evenly and braked in a controlled manner, even at high plant speeds.

Squeezing rolls ensure lower residual moisture than rubber or polyurethane coatings. Due to the capillary or suction effect of the non-woven fabric, fluid displacement in the edge area is reduced and the strip edges dry better. In addition, the material properties of nonwovens also come into play in terms of cut resistance and service life.

Due to their sponge effect, non-woven fabric covers can be used as oiling or application rolls for the even application and distribution of various liquid coatings. Due to their porosity and pore volume, they are able to absorb liquid and dispense it evenly over the surface under pressure.

5. The same applies to the use of non-woven rollers as transport and carrying rolls. The soft and absorbent roller surface prevents scratches and damage and ensures gentle strip transfer.

6. The special surface protection achieved by absorbing small dirt particles into the roller surface is used in pressure rolls made of non-woven fabric, especially for soft and sensitive surfaces, for example when coiling aluminium strips in the cold rolling process.

Solutions.

NTX Neutral Mill Rolls

Squeezing, oiling, de-oiling, tensioning/braking, pressing, pulling, deflecting, feeding, transporting

- Reduced replacement, inventory, maintenance, energy and fluid costs

- Reduced fluid usage

- Reduced dirt through Absorption

- Reduced defects on coil

- Increased line speed and uptime

- Cost effective

NTX Chemical Mill Rolls

Wringing, Deflecting

- Reduced replacement, inventory, maintenance, energy and fluid costs

- Reduced fluid usage

- Reduced fluid contamination

- Increased line speed and uptime

NTX Wheels

Transport, Guiding, Carrying

- Reduced replacement, inventory and maintenance costs

- Reduced slippage

- Increased line speed

- Increased process control

NTX Wiper Bars

- Reduced residual oil or other fluids on the surface

- Reduced defects on the coil

- Increased servicelife

General Information.

Rubber Rolls vs. Non-Woven Rolls

| Rubber Rollers | Osborn NTX Mill Rolls |

|---|---|

| Short life – non compressible, susceptible to cuts, causes more downtime | Long life – compressible resist cutting for more uptime |

| Can limit line speed due to hydroplaning because of closed, non porous surfaces |

Line speed – porous, open surface for consistent strip contact can allow higher line speeds |

| Non-repairable | Repairable for better return on investment |

| Cuts propagate causing excessive fluid pass-through and reduced lifetime | Self-healing for superior fluid control |

| Low coefficient of friction on wet/oiled surface conditions | High coefficient of friction on many surfaces, even wet, for better strip control |

Non-woven rolls can be used in all strip lines or rolling mills for steel, stainless steel, aluminium and non-ferrous metals. They include:

- Hot-Dip Galvanizing Lines

- Continuous Annealing Lines

- Annealing and Pickling Lines

- Cold Rolling Mills

- Skin-Pass Mills

- Colour and/or Organic Coating Systems

- Electrolytic Galvanizing Lines

- Cleaning or Degreasing Lines

- Tube and Profile Production

and a whole range of other types of line.

They also significantly contribute to improving product and process quality.

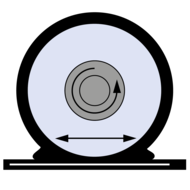

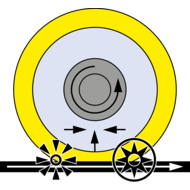

Material Compressibility of Non-Woven

- Non-woven material compresses which results in damming effect, liquid is absorbed into roll cover due to capillary effect

- Nip area stays compressed and completely sealed

- Non-woven material decompresses, resulting in absorbtion of excess fluid; thin, consistent and determinable film is left on the sheet surface; precise film thickness can be determined by material density and roll pressure selection

Rubber Roll

Non-Woven Roll

1: Oiled Aluminium;

2: Dry Aluminium;

3: Oiled Steel;

4: Dry Steel