Edge rounding

In contrast to deburring with wire, the abrasive grains embedded in the plastic fibers work against the workpiece edge with rotation and feed and round it off. Different rounding sizes can be achieved by changing the setting parameters.

About Edge Rounding.

If an edge rounding is required in addition to the deburring process, a defined and constant edge rounding can be achieved with the ATB® brushes with abrasive nylon.

In contrast to deburring with wire, the abrasive grains embedded in the plastic fibers work against the workpiece edge with rotation and feed and round it off. Different rounding sizes can be achieved by changing the setting parameters.

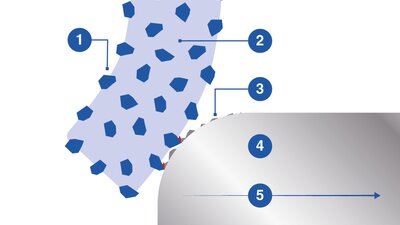

(1) Abrasive Grit, (2) Synthetic Fibre, (3) Chip/Burr, (4) Workpiece, (5) Cutting Direction

For which applications is Edge Rounding useful?

Edge rounding is used on a wide variety of workpieces. The determining requirement for the filleting can also be as varied.

Possible objectives of the geometric modification of the component may include:

- Safety aspect: reduction of the risk of injury from cuts

- Hygiene aspect: ease of cleaning the surface

- Reduction of tool wear: rounding of cutting edges to increase tool life

- Preparation for subsequent surface coating: Geometry enables more uniform layer thicknesses and reduces the risk of corrosion on thin-walled components

The following is a list of practical examples where edge rounding can be achieved with the aid of technical brushing solutions:

- Tools (e.g. cutting tools such as drills)

- various milled and turned parts

- workpieces made of sintered metal

Products for

Edge rounding.

ATB® disc brushes with maximum fill density, for shell mill mount

Evolution

For direct mounting on shell mill holders without need of further clamping set / system.

ATB® disc brushes with maximum fill density, Turbo-line

Evolution

Brushes for use on continuous deburring systems with planetary heads.

ATB® disc brushes with maximum fill density, compatible with clamping fixture

Evolution

Can be used for deburring components made of the most diverse of materials, such as steel, aluminium and cast iron.

ATB® disc brushes with maximum fill density, for tool holders

Evolution

For deburring sealing and contact surfaces. The application should take place on stationary machines. Use with cooling lubricant, water, oil is recommended.

ATB® wheel brush with full trim, shank adaption

Evolution

ATB® wheel brush with shank for direct adaption on several tool holders. Please ask our application technicians for open requests and general questions about the ATB® products.

Clamping fixtures for ATB® disc brushes with shank and clamping surface

Evolution

Clamping fixtures with shank-Ø 12 mm and clamping surface DIN 6535-HB. Compatible with ATB® disc brushes including a hexagonal mounting bore.

ATB® end brush, shank adaption

Evolution

ATB® end brush with shank for direct adaption on several tool holders. Please ask our application technicians for open requests and general questions about the ATB® products.

ATB® wheel brush with full trim, Cutter head holders/combined cutter arbor

Evolution

ATB® wheel brush with longitudinal groove for direct clamping on tool holders (e.g. HSK, SK, BT) as cutter head holders and combi milling arbor holders. Please ask our application technicians for open requests and general questions about the ATB® products.