Industrial Polishing

Surface treatment is a vast field in which mechanical treatment and polishing technology play an essential role, hence Osborn's major role.

Solution for industrial polishing

Our wide range of tools has been in use for decades by renowned companies all over the world.

These high-performance tools can only be produced using high-quality raw materials and modern machinery. The many years of experience of our engineers combined with the latest technological developments enable us to supply special tools for all mechanical surface treatment operations.

Thanks to our long-standing cooperation with machine manufacturers and our customers, we have a team of experts at your disposal to offer you a no-obligation advice and testing service. Our in-house testing department can simulate all the usual industrial manufacturing methods in a variety of fields.

Our applications engineers can not only study your manufacturing systems, but also define a range of tools and working parameters that will enable you to achieve better surface finishes, without disrupting your production.

The esteem in which our tools are held grows with the demands of our customers. While respecting tradition, Osborn Unipol strives to advance the technology of mechanical surface treatment by marketing innovative products.

Current applications

The following examples are only an indication of the wide range of applications covered by the Osborn product range. There are several alternative products for almost every process. For more details please feel free to contact our

Customer Service Engineers, they are always at your disposai to help with your surface finishing needs.

Sheet metal finishing

Steel strip is mechanically deaned and roughened on a conveyor line using :

- LIPPERT-UNIPOL abrasive bristle spiral brushes

- LIPPERT-UNIPOL non abrasive spiral rollers

- LIPPRITE" non-woven flap rollers

Finishing pots and pans

- Grinding with abrasive flap wheels

- Pre-polishing with ventilated impregnated sisal and cloth buffs

- Polishing with ventilated non-impregnated sisal/cloth, cloth or Notiflex® buffs

- Hi-gloss finish with ventilated buffs in cloth or Notiflex®.

Cutlery processing

- Pre-polishing with sisal/cloth buffs or impregnated sisal cord buffs

- Polishing with ventilated sisal/cotton buffs, sisal cord buffs or Notiflex® discs

- Finishing with ventilated cloth or Notiflex® discs

- Satin finishing with Lipprite® flap wheels or impregnated tampico fibre brushes.

Sanitary fittings and builders hardware

- Polishing with ventilated cloth or Notiflex® buffs

- Finishing with ventilated cloth or Notiflex® buffs

- Satin finishing with Lipprite® flap wheels.

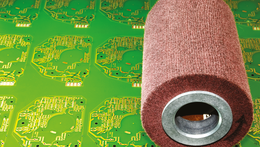

Mechanical processing of printed circuits boards

- Deburring with Lipprox®

- Cleaning and deoxidation with Lipprite® rollers

- Cleaning, deoxidation and scrubbing with non-abrasive nylon and pumice

- Finishing with Lipprite® rollers

- Cleaning of press plates with Lipprite® or Lipprox® rollers.

Wood industry

- Fine sanding with Lippryll® coated abrasive rollers

- De-nibbing with Lipprite® or Lippryll® rollers

- Antique finishing with abrasive bristle spiral rollers

- Sanding of profiles with Lipprox® wheels

- Glossing varnished parts with Notiflex® buffs.

Polishing ciompounds liquid and solid

Osborn produces a very wide range of polishing compounds in liquid and solid form. These excellent quality compounds are a natural complement to the various polishing tools presented in the previous pages. Our technical teams are at your disposal to advise you and help you define the most suitable compound for your application.

Liquid compounds (Polish)

Liquid compounds are mainly used on automatic polishing machines. The use of a liquid compound allows a polishing operation at a lower temperature. The paste is stored in pressurized tanks or reusable containers with diaphragm pumps. For industrial productions using large quantities, a centralized feeding system ensures a continuous flow of product, reduces downtime and increases productivity.

Solid compounds

Originally, compounds were only used for manual polishing on a lathe. This is still one of its main uses today and traditionally very important at Osborn. The increasing use of polishing robots with adapted bar formats also makes it possible to achieve economical polishing for small and medium series and complicated high-precision parts. Osborn offers "special bars" in all existing widths. Suitable for industrial and individual use, for example for manual machines, Osborn offers you products that are widely approved on an industrial scale, in various shapes and dimensions.

Industrial Polishing

Products.

DIALUX® Green

Evolution

High-gloss polishing compound of hard alloys such as white gold, platinum and silver.

Osborn Classic Compound P3000

Evolution

P3000 belongs to the Classic Compound series, our top sellers from the Unipol/Langsol range. The range includes compounds for every polishing stage (brushing, polishing, colouring, super finishing). Best results are achieved when used with Osborn polishing rings. P3000 (white) is excellent for stainless steel.

Osborn Classic Compound C2000

Evolution

C2000 belongs to the Classic Compound series, our top sellers from the Unipol/Langsol range. The range includes compounds for each polishing stage (brushing, polishing, colouring, super finishing). Best results are achieved when used with Osborn polishing rings. C2000 (blue) is a colouring compound for stainless steel.

Osborn Classic Compound C1000

Evolution

C1000 belongs to the Classic Compound series, our top sellers from the Unipol/Langsol range. The range includes compounds for every polishing stage (brushing, polishing, colouring, super finishing). Best results are achieved when used with Osborn polishing rings. C1000 (beige) is a colouring compound for lacquers and plastics.

Osborn Classic Compound P4000

Evolution

P4000 belongs to the Classic Compound series, our top sellers from the Unipol/Langsol range. The range includes compounds for every polishing stage (brushing, polishing, colouring, super finishing). Best results are achieved when used with Osborn polishing rings. P4000 (light green) is a polishing compound for stainless steel.

Osborn Classic Compound F2000

Evolution

F2000 belongs to the Classic Compound series, our top sellers from the Unipol/Langsol range. The range includes compounds for every polishing stage (brushing, polishing, colouring, super finishing). Best results are achieved when used with Osborn polishing rings. F2000 (light orange) is a super finishing compound for the deepest, streak-free shine.