Polishing for Luxury Industries

Perfectly polished surfaces are a key quality feature in the jewelry and accessories industry. Our polishing compounds and buffs are specifically designed for working with different materials, enabling efficient and controlled polishing. The result: durable, flawless finishes that meet the highest standards of the luxury sector.

The Right Solution for

Every Application and Every Workpiece

Stainless Steel

Stainless steel is not only valued for its strength and durability — it also has an important role in the luxury industry. High-quality stainless steel serves as the base material for premium accessories and timepieces.

Finishing Stainless Steel Parts

Osborn abrasive tools, polishing tools and compounds are applied after grinding, to achieve a whole range of different finishes.

Osborn tools and compounds are made for automated processes demanding the highest level of reproducibility, with the best price: performance ratio. Tools and compounds for flatbed and robotic equipment are complemented by alternative products for manual applications.

Brass

Brass parts serve as the base for a wide variety of components such as chandeliers and decorative elements used in luxury interiors. Luxury elements are often made from brass that must be polished prior to a subsequent plating process.

Finishing Brass Parts

The range of polishing compounds and polishing tools are specially tailored for brass parts, to ensure a finish of the highest level and absolute reproducibility. Depending on current trends and customer requirements, the final surface can be polished or finished to a high-gloss shine.

Precious Metals

Precious metals are made from naturally occurring metals. Due to the rarity of these metals, they are generally high in value. The most common precious metals include: gold, silver, platinum, palladium and titanium. Due to their natural lustre, these metals differ from other base metals and are therefore the material of choice for jewelry.

Finishing Precious Metals

Precious metals, by their very nature and cost, are used in the production of luxury items. The polishing process therefore brings a strong added value to these products. Watchmaking, jewelry, luxury parts, high end electronic parts and medical implants all depend on the special characteristics of precious metals. Polishing processes are especially selected to achieve a perfect gloss without any aggressive action that could remove too much material or damage the contours of parts that are often very small.

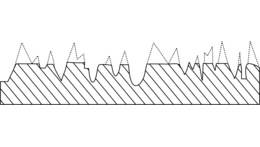

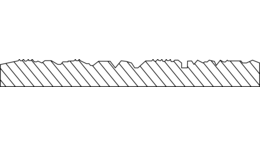

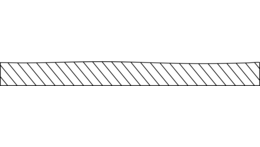

Polishing Steps

Cutting

Cutting is the first step in a three-step polishing process.

Defects and deep scratches on the surface of the workpiece are removed.

Polishing

Polishing is the second step in a 3-step polishing process.

Here, cut marks and traces from the cutting process are removed and the surface is levelled.

Colouring/High-Gloss Polishing

Creating a high-gloss surface, colouring is the third and final step in a 3-step polishing process.

Solid Polishing Compounds

Ingredients:

- Free of animal fat and animal tissue

- Free of contamination or odour

- No hydro carbons

- No solvents or silicia

- Non-hazardous

Storage Recommendations:

- Store the compound in cool and dry conditions at approx. 20°C (for shorter periods at 5°C-30°C)

- Storage area should be well-ventilated to avoid temperature fluctuations

- Boxes should remain closed to prevent contamination and the absorption of humidity

- Observe shelf life and check our guidelines mentioned on our compound labels

Do not store together with:

- Explosive or hazardous substances

- Oxidizing substances

- Radioactive substances

- Food or feeding substances

Protect from:

- Frost

- Heat

- Sunlight or UV radiation

- Humidity

- Rainwater

- Damage

| Manual Polishing | Automatic Polishing | ||

|---|---|---|---|

| Recipe | S-Box | Sized Bars | Round Bars |

| (approx. 400 gr.) | (approx. 900 - 4.500 gr.) | (approx. 900 gr.) | |

| 6310 | ● | ● | ● |

| 1128G | ● | ● | ● |

| 1132D | ● | ● | ● |

| 466 | ● | ● | ● |

| 1461 | ● | ● | ● |

| OURO | ● | ● | ● |

| Unipol Gold | ● | ● | |

| 9510 Gold Easy | ● | ● | ● |

| 9495 Gold Dry | ● | ● | |

| Eclat | ● | ● | ● |

| Osborn 9750 | ● | ● | |

Additional compound types are available upon request.

Trusted Compounds for Luxury Polishing

Luxury products are finished in a manual or automatic operation by experts. Osborn recommends the following solid compounds for this process. Since non-ferrous metals or stainless steel may form the basis of high-end products, suitable compound recommendations are included.

Stainles Steel

| Recipe | Colour | Free of animal fat | Cutting | Polishing | Colouring | Fat | Cut | Colour |

|---|---|---|---|---|---|---|---|---|

| 6310 | Grey | ✓ | ● | 3 | 7 | 5 | ||

| 1128G | Dark pink | ✓ | ● | 6 | 6 | 3 | ||

| 1132D | Dark pink | ✓ | ● | 5 | 5 | 4 | ||

| 466 | Red | ✓ | ● | 4 | 5 | 6 | ||

| 1461 | White | ✓ | ● | 2 | 3 | 8 | ||

| OURO | Pink | ✓ | ● | 2 | 2 | 9 | ||

| Unipol Gold | Gold | ✓ | ● | 1 | 1 | 10 | ||

| 9510 Gold Easy | Cream | ✓ | ● | 1 | 2 | 10 | ||

| 9495 Gold Dry | Yellow | ✓ | ● | 1 | 2 | 10 | ||

| Eclat | Yellow | ✓ | ● | 1 | 1 | 11 | ||

| Osborn 9750 | White | ✓ | ● | 1 | 2 | 12 |

Performance 1 = low / 12 = high

Brass

| Recipe | Colour | Free of animal fat | Cutting | Polishing | Colouring | Fat | Cut | Colour |

|---|---|---|---|---|---|---|---|---|

| 6310 | Grey | ✓ | ● | 5 | 8 | 5 | ||

| 1128G | Dark pink | ✓ | ● | 6 | 7 | 3 | ||

| 1132D | Dark pink | ✓ | ● | 5 | 6 | 4 | ||

| 466 | Red | ✓ | ● | 6 | 7 | 5 | ||

| 1461 | White | ✓ | ● | 3 | 4 | 8 | ||

| OURO | Pink | ✓ | ● | 3 | 3 | 8 | ||

| Unipol Gold | Gold | ✓ | ● | 3 | 2 | 9 | ||

| 9510 Gold Easy | Cream | ✓ | ● | 2 | 2 | 10 | ||

| 9495 Gold Dry | Yellow | ✓ | ● | 1 | 3 | 10 | ||

| Eclat | Yellow | ✓ | ● | 1 | 3 | 10 | ||

| Osborn 9750 | White | ✓ | ● | 1 | 3 | 11 |

Performance 1 = low / 12 = high

Precious Metals

| Recipe | Colour | Free of animal fat | Cutting | Polishing | Colouring | Fat | Cut | Colour |

|---|---|---|---|---|---|---|---|---|

| 1461 | White | ✓ | ● | 3 | 4 | 7 | ||

| OURO | Pink | ✓ | ● | 3 | 3 | 8 | ||

| Unipol Gold | Gold | ✓ | ● | 3 | 2 | 9 | ||

| 9510 Gold Easy | Cream | ✓ | ● | 2 | 2 | 10 | ||

| 9495 Gold Dry | Yellow | ✓ | ● | 1 | 2 | 10 | ||

| Eclat | Yellow | ✓ | ● | 1 | 2 | 10 | ||

| Osborn 9750 | White | ✓ | ● | 1 | 2 | 12 |

Performance 1 = low / 12 = high

Sisal and Sisal Cloth Buffs

Sisal is a natural material, perfect for the first steps in the polishing process. Sisal buffs are aggressive and often follow a grinding step with coated abrasive or non-woven tools.

Pleated Sisal Cloth Buff

Regular folds with a sandwich of sisal web and cotton cloth, make the Osborn Pleated Sisal Cloth Buffs, an aggressive tool with good compound retention.

Used together with Osborn cutting compounds, these buffs are an excellent cutting tool for contoured parts.

Airflow Sisal Cloth Buff

A flexible and economical cutting tool with irregular folds of sandwiched sisal and cotton cloth. Buffs can be mounted together to form a wider surface when polishing larger surfaces, particularly on small rotary table machines.

A special soft treatment: extends service life and results in a more uniform finish. Airflow Mini Sisal Cloth Buff: a smaller 100mm version is also available.

Airflow Sisal Buff

A compact buff, purely made of sisal web. Lacking in flexibility, it is a hard and aggressive tool.

Together with Osborn cutting compounds, Sisal buffs may be used in the cutting process of stainless steel or brass, which form the base of buckles, clasps and even screws required for luxury products.

Airflow Sisal Cord Buff

The most flexible tools in the sisal range. Individual plaited cords wrap around contours, retaining sufficient cut in a cool process.

Airflow Sisal Cord Buffs are used primarily in the polishing of shaped parts.

Sisal Cloth Mop

Discs of treated or gray cloth are twisted and layered with sisal web to form an economical and low cost cutting tool.

Mops are the product of choice when there are limitations on diameter used.

Sisal Types

Sisal is available as a woven fabric, sandwiched with cloth or plaited in to cord.

| Type | Characteristics | Grade | |

|---|---|---|---|

| Sisal Web | 82B | dense structure, thin yarn | light/medium |

| Sisal Cloth | 82B/301J | suitable for Pleated Buffs | medium/hard |

| 82B/101B | suitable for Pleated and Airway Buffs | light/medium | |

| Sisal Cord | 32 | two cords twisted | light |

| 48 | eight cords braided | heavy | |

Cloth Buffs

All Osborn buffs are made with top quality based cloth, ensuring their resilience and long service life.

Pleated Cloth Buff

The flat, regular pleats offer an excellent surface for retention of Osborn solid compounds.

The hardness and flexibility of this buff depends on whether a mill-treated cloth, a standard cloth or a raised cloth is selected, this plus the choice of Osborn compound determines the polishing results.

Pleated Cloth Buffs are particularly suitable for manual polishing.

Airflow Cloth Buff

The standard ventilated buff which is suitable for almost every step in the polishing process.

Various qualities of mill-treated, grey or light cloth can be selected, depending on the results required.

The irregular folds fixed to a metal clinch ring, form a flexible and economical buff. Buffs can be used individually or mounted on a shaft, depending on the available equipment. All grades of material can be matched to the Osborn polishing compounds.

Harder cloths for cutting with Unipol 1128G or lighter cloths for polishing with 466.

Airflow Mini Cloth Buffs in diameters of just 100mm are available, a perfect finishing tool small parts.

Cloth Mop

Discs of material are layered and stitched to a required width. Layers are arranged such that any fraying is minimal. By varying the grade of cloth and the stitching, different hardness’s can be determined.

Cloth mops are used in manual finishing processes on small parts like buckles or clasps.

Loose Discs

Loose discs are available in all cloth types indicated on the next page. They are supplied in all diameters required for standard equipment. Loose discs adjust to different shapes and contours. Each single layer is flexible and able to fit into the narrowest of parts.

Loose discs can be mounted together to form whatever width is required. They are also suitable for tapered shafts.

Cloth Types

Allow our experts to advise you on the most suitable cloth types for your specific polishing process.

| Type | Reference | Colour | Characteristics | Application |

|---|---|---|---|---|

| Treated Cloth | 301J | Yellow | Densely woven cloth, hard but thin | Cutting |

| TT | Orange | Hard but dry cloth | Cutting & Polishing | |

| BSKY | Blue | Flexible cloth with high resilience | Cutting & Polishing | |

| Polishing Cloth | 298 | Grey | Harder, all round cloth, well balanced | Cutting & Polishing |

| 290 | Grey | Medium hardness, densely woven cloth | Cutting & Polishing | |

| 3260 | Grey | Light, medium hard, flexible cloth (mainly for cloth mops) | Polishing | |

| 202 | Grey | Soft cloth, medium quality | Polishing | |

| 101A | Grey | Soft standard cloth | Polishing | |

| 1120 | White | Soft but heavy cloth, suitable for all metals | Polishing | |

| Light Cloth | 5300 | Grey | Very light, densely woven cloth (mainly for cloth mops) | Polishing & Colouring |

| 5310 | White | Light cloth used on non-ferrous metal (mainly for cloth mops) | Polishing & Colouring | |

| 6420 | White | Versatile white cloth used on all metals (mainly for cloth mops) | Polishing & Colouring | |

| 6450 | Grey | Super fine finishing cloth used on all metals (mainly for cloth mops) | Colouring | |

| 6570 | Grey | Like 6450 but softer, used on all metals (mainly for cloth mops) | Colouring | |

| RaisedCloth | MO4 | Grey | Soft cloth, raised on one side | Colouring |

| MO5 | Grey | Soft cloth, raised on both sides | Colouring | |

| 206SG | Grey | Dense cloth, raised on both sides, some elasticity | Colouring | |

| M310 | White | No.1 soft cloth, raised and bleached | Colouring |

Abrasive Non Wovens

Abrasive non wovens consist of tangled nylon and/or polyester web with different types of abrasive grit particles resin bonded to the fibres. The material has an open and flexible structure. It achives a uniform and consistent finish, whether on a flat or slightly profiled surface. Abrasive grit particles are usually Silicon Carbide or Aluminium Oxide. The material can be used in both wet and dry operations.

LIPPROX® Wheel

Non woven abrasive web is wound around a core and specially treated, resulting in a consistent hardness and level of abrasion over the life of the product. This convolute wheel is perfect for light deburring. An arrow indicates the direction in which the Lipprox® Wheels must be used.

LIPPRITE® Wheel

Non woven abrasive flaps are bonded radially to a phenolic tube. Hardness can be varied by increasing or decreasing the number of flaps. The three-dimensional open web ensures a self-cleaning action for easy removal of surface contamination. Depending on the process, a technically defined surface result or a visual surface can be achieved. Lipprite® Wheels are extremely versatile in satin finishing operations.

Waved Non Woven Buff

The waved construction allows for a high-density buff with minimal flexibility, an advantage when good cutting action and a uniform surface are required.

Airflow Non Woven Buff

Usually 4 layers of non woven are fixed to a metal clinch ring. The irregular folds offer a versatile satinising tool that performs best when minimal pressure is applied, this in turn increases the surface life of the Airflow. This is a highly economical buff.

Abrasives Non Woven Types

A selection of the most standard non woven types.

| Osborn | FEPA | |

|---|---|---|

| Type | Grade | Norm |

| A2 | A Coarse | AL2O3 80 |

| A4 | A Medium | AL2O3 120 |

| A6 | A Fine | AL2O3 180 |

| A7 | A Very Fine | AL2O3 240/320 |

| S4 | S Medium | SiC 120 |

| S6 | S Fine | SiC 180 |

| S7 | S Very Fine | SiC 240-320 |

| S8 | S Super Fine | SiC 500 |

| S9 | S Ultra Fine | SiC 800 |

| S10 | S Ultra Fine | SiC 1000 |

Coated Abrasives

Osborn offers a range of coated abrasive tools, making the most of the best materials on the market and our manufacturing expertise.

Coated Abrasive Flap Wheels

Tightly packed coated abrasive flaps arranged around a core, make an effective grinding tool prior to polishing. Round parts and tubes benefit from this product, with its long life and ability to continually reproduce the same surface.

Small Abrasive Flap Wheels with Shank

Small abrasive flap wheels on a 6 mm shank are available in non-woven, coated abrasive or a combination of both. They are suitable for use on power drills and high speed machines. These wheels reach areas that are difficult to access. They adapt well to contours and produce a smooth uniform satin finish.

Type and Grit

| Grit | 40 | 60 | 80 | 120 | 150 | 240 | 320 |

|---|---|---|---|---|---|---|---|

| Standard | ● | ● | ● | ● | ● | ● | ● |

Accessories

Metal Centreplates, Nylon and Aluminium accessories can be used to reduce the inside diameter of Buffs.

Centreplates

Centreplates with ventilation holes are required to reduce the inside diameter of buffs to a bore size that suits the shaft on to which they are to be mounted. Metal centreplates are re-usable.

Interchangeable Metal Adapters

Small centreplates are specifically to reduce the buff inside diameter of 31.75 mm to a smaller size.

Nylon Centreplates and Spacer

Nylon centreplates are used to reduce the inside diameter of the buff, they can also be supplied as a combination of centreplate and spacer for quick and efficient mounting.

Mandrel

Mandrels in 6 mm are available to clamp polishing or satin finishing buffs with an inside diameter of 10 mm to 100 mm. Parts can then be used on a power drill. Mandrels are intended for repeated use.

The Right Combination

for Each Step of the Process

No two customers are alike. Osborn experts are always keen to talk and identify tools, compounds and parameters that will achieve the best possible result on a given part. For now, we should just like to present some examples.

Brass

| Cutting | Polishing | Colouring | |

|---|---|---|---|

| Buff | Cloth Mop TT | Pleated LM EK 6420 | Loose discs M310 |

| Compound | 1132D | 1461 | Ouro |

Stainless Steel

| Cutting | Polishing | Colouring | |

|---|---|---|---|

| Buff | Sisal cotton Stiched Mop | Lose discs 6420 | Loose discs M310 |

| Compound | 1128G | 1461 | Eclat |

Gold and Silver

| Cutting | Polishing | Colouring | |

|---|---|---|---|

| Buff | - | Cloth Mop or Loose Disc 6420 | Cloth Mop or Loose Disc M310 |

| Compound | - | 1461 and Ouro | 9495 Gold Dry |

Platinum

| Cutting | Polishing | Colouring | |

|---|---|---|---|

| Buff | Cloth Mopp TT | Cloth Mop or loose Disc 6450 | Cloth Mop or Loose Disc M310 |

| Compound | 6310 | 1461 | Eclat |

Recommended Cutting Speeds (m/s)

| Material | Cutting | Polishing | Colouring |

|---|---|---|---|

| Stainless Steel | 25-30 | 20-25 | 15-20 |

| Brass | 25 | 16-22 | 13-18 |

| Precious Metals | - | 16-22 | 13-18 |