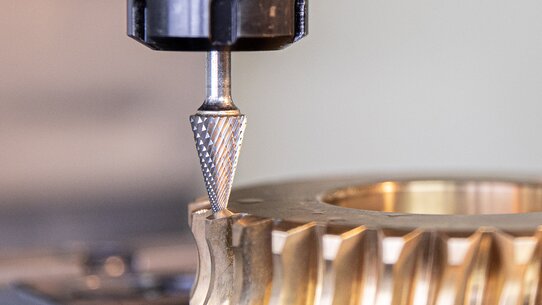

Highest precision and cutting performance: Osborn carbide burrs

Osborn is expanding its range to include high-precision carbide burrs. The world's largest supplier of solutions for mechanical surface finishing now also offers a complex programme of carbide burrs for machining a wide range of workpiece geometries...

Made in Germany

Osborn carbide burrs are manufactured with the highest precision on the latest generation of CNC machines. The "Made in Germany" production guarantees a consistently high quality of these tools.

Highest precision, high cutting performance

Thanks to optimally matched cutting geometry and toothing, our carbide burrs achieve a high material removal rate. This guarantees the best work results with the highest precision. They are suitable for universal use on the most important industrially used materials, such as stainless steel, steel, cast iron and non-ferrous metals.

Common types also available as kits

The most popular five cutter shapes are also offered with cross serration Z6 as a set in a practical storage box. The cross-toothing ensures high material removal and the five cutter shapes allow the machining of a wide range of workpiece geometries.

Optinal 30% more stock removal - Shipyard special toothing

For users who value a further 30% increase in cutting/removal performance, Osborn offers the SHIPYARD special toothing with optimised cutting angle for all milling head shapes.

Customised solutions

Customised solutions with special toothings, other shank lengths or deviating dimensions and smaller batch sizes are also possible at any time on request.

High cutting performance with Osborn carbide cutters.