Deburring

Mechanical processing (e.g. turning, milling, punching, lasering) produces edges, splinters, or fraying on the workpiece due to the displacement of material. These are referred to as burrs. Steel, aluminum, castings, and forgings are the main materials being deburred, but burrs also occur on wood or plastic parts.

About Deburring.

Mechanical processing (e.g. turning, milling, punching, lasering) produces edges, splinters, or fraying on the workpiece due to the displacement of material. These are referred to as burrs. Steel, aluminum, castings, and forgings are the main materials being deburred, but burrs also occur on wood or plastic parts.

Which deburring methods exist?

There are different methods to remove burrs. These include brushing and grinding, vibratory grinding, but also thermal or electrochemical deburring and deburring using a high-pressure water jet.

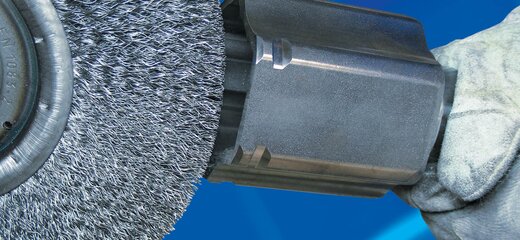

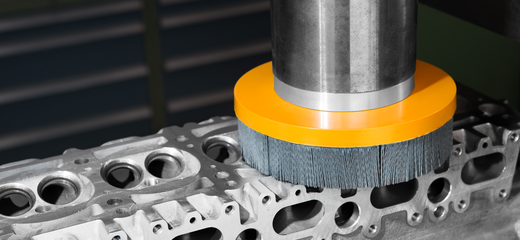

Deburring can be performed with hand tools and power tools. In production environments, where high quantities are produced and process times and costs per part are important, workpieces are deburred automatically in machining centers and robot cells. In order to keep process times short, deburring is usually carried out in the same machining center in which the previous machining operation took place. Highly efficient brushes are used here, sometimes with the use of cooling lubricants.

To determine the appropriate deburring tool, the position of the burr and its accessibility, as well as the material of the workpiece and also the thickness of the burr must be analyzed.

What types of burr are there?

There are five different types of burrs. The difference is mainly defined by the size and by the respective machining process.

Burr class 1 - tinsel burr

It is usually caused by fine grinding. It is only a very small burr that is minimally connected to the workpiece. It is extremely easy to remove.

Burr class 2 - small burr base

It occurs during grinding and is larger than the tinsel burr. The burr is connected to the workpiece and must be removed mechanically.

Burr class 3 - Large burr

It is also connected with the workpiece. Its size is similar to class 2. However, it is shaft-edged. As a rule, burrs of this type are formed by milling.

Burr class 4 - With a large foot

The foot of the burr is significantly larger than in class 3. Accordingly, the burr is firmly attached to the workpiece. It is created by processes such as slotting, broaching, or turning.

Burr class 5 - displaced material

The cutting tool virtually pushes the material in front of it. Aggressive machining is necessary to remove such burrs.

How do I find the right fill material for my burr?

The burr class, the position of the burr and the material of the workpiece to be processed are decisive for identifying the right fill material.

The larger the burr to be removed, the coarser the grain size of the abrasive fill and the larger the selected wire diameter should be.

|

Burr |

Workpiece shape / |

Workpiece material | ||||

|---|---|---|---|---|---|---|

| Steel | Stainless Steel | Aluminium | Cast | Non-ferrous metal | ||

| 1 | Flat Surface | CER 320 / SIC 320 | CER 320 / SIC 320 | SIC 320 | ST 0,20 | SST 0,20 |

| Complex Geometry | CER 320 / SIC 320 | CER 320 / SIC 320 | SIC 320 | ST 0,20 | SST 0,20 | |

| Bore | SIC 320 / ST 0,08 | SIC 320 / SST 0,08 | AO 600 | ST 0,20 | SST 0,20 | |

| 2 | Flat Surface | CER 180 / SIC 180 | CER 180 / SIC 180 | SIC 180 | ST 0,20 | SST 0,20 |

| Complex Geometry | CER 180 / SIC 180 | CER 180 / SIC 180 | SIC 180 | ST 0,20 | SST 0,20 | |

| Bore | SIC 180 / ST 0,13 | SIC 180 / SST 0,13 | AO 600 | ST 0,20 | SST 0,20 | |

| 3 | Flat Surface | CER 120 / SIC 120 | CER 120 / SIC 120 | SIC 120 | ST 0,20 | SST 0,20 |

| Complex Geometry | CER 120 / SIC 120 | CER 120 / SIC 120 | SIC 120 | ST 0,20 | SST 0,20 | |

| Bore | SIC 120 / ST 0,13 | SIC 120 / SST 0,13 | SIC 120 | ST 0,20 | SST 0,20 | |

| 4 | Flat Surface | CER 80 / SIC 80 | CER 80 / SIC 80 | SIC 80 | ST 0,20 | SST 0,20 |

| Complex Geometry | CER 80 / SIC 80 | CER 80 / SIC 80 | SIC 80 | ST 0,20 | SST 0,20 | |

| Bore | SIC 80 / ST 0,20 | SIC 80 / SST 0,20 | SIC 80 | ST 0,20 | SST 0,20 | |

| 5 | Flat Surface | Tungsten Carbide Burrs | ||||

| Complex Geometry | ||||||

| Bore | ||||||

CER: Ceramic, SIC: Silicone carbide, AO: Aluminium oxide, ST: Steel wire, SST: Stainless steel wire