Case Studies

Revolutionizing Turbine Component Cleaning

Manual cleaning slowed production to a crawl—until Osborn stepped in

Solution used: ATB Internal Finishing Brushes

In-Machine Deburring, Fully Realized

A custom problem needs a custom solution.

Technologies used: Custom Brush Design

Aerospace Turbine Parts

Evaluate a manual secondary finish operation of aerospace turbine parts and provide an optimized brush solution.

Solution used: Automated finishing process utilizing an Osborn ATB™ Silicon Carbide End Brush

Customer savings: $50,000 annually

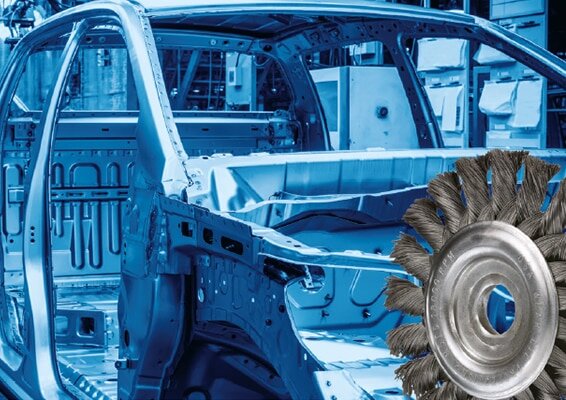

Automotive–Tier 2 Automotive Supplier

Osborn delivers superior finishing solutions saving the customer $10,000 annually.

Solution used: Heavy Duty Knot Wire Wheel Brush featuring Osborn’s proprietary TufWire™

Cleaning Chemicals

Osborn provides cleaning solutions for your most challenging applications.

Technologies used: Custom formulated chemical cleaners

Customer savings: > $250,000 per year

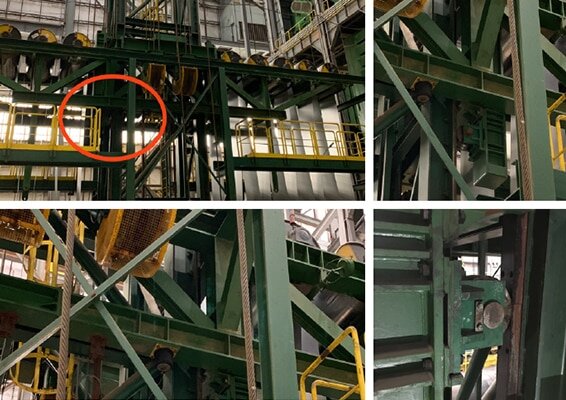

Cold Mill and Galvanization Line

A Major Steel Company needed a solution for the complicated bearing/guide roller.

Technologies used: Guide/Roller assembly

Elevator Hoistway Pressurization

Whether retrofitting an existing building or working on new construction, it is necessary to satisfy fire safety regulations for elevator pressurization.

Solution used: Strip Brushes

Performance Exhaust

Osborn provides world-class finishing solutions for a high performance exhaust manufacturer, resulting in radical cost savings and reduced downtime.

Solution used: Ceramic Grain ATB™ Brush

Customer savings: $120,000

Transformer Component Cleaning & Finishing

Osborn provides best-in-class finishing solution and lead times to a premium quality power supply manufacturer, resulting in significant cost savings and less changeovers.

Solution used: Crimped Wire Wheel Brush

Customer savings: $10,000 Annually

Bakery

A major bakery in the United States has a Tromp – Netherlands – waffle oven.

Solution used: High Temp Sealeze Brush

Customer savings: 4.7% efficiency