Roller Brushes

From start to finish, Osborn has your back with trusted solutions.

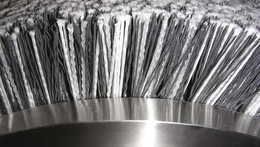

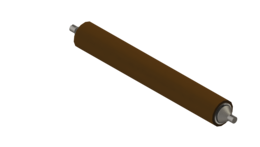

Brush Rolls

Osborn offers multiple types of expertly designed brush rolls for various stages of the manufacturing process. HDL® brush rolls raise the bar on degreasing and cleaning strip surfaces, meeting rigorous technical requirements and exceeding quality standards. Helimaster® brush rolls are ideal for cleaning and as backup rolls in wet or dry operated rolling and skin pass mills, removing oxides, dirt, and rolling residuals.

Brush rolls are designed to improve repeatability, increase process times and enhance the quality of the final product.

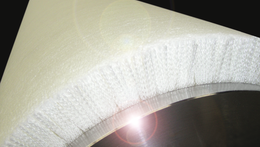

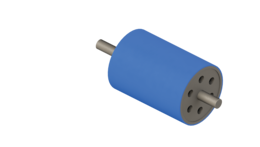

Furnace Rolls

With decades of experience collaborating with leading equipment manufacturers, Osborn brings unmatched application expertise to the design and manufacturing of furnace rolls.

Our furnace rolls are an important part of our global customers’ complex metal technology processes and are designed to perform under rigorous conditions in continuous processes up to 1,300°C. Beyond manufacturing, Osborn extensively tests rolls to ensure proper sheet tracking. The entire furnace zone is tested. Tracking is simulated on an in-house test system to guarantee optimal performance when installed in new furnace lines. In addition, these rolls can be recovered when worn.

Osborn furnace rolls are designed to provide optimum tracking through the furnace and prevent both scale pick-up and spot formation on the surface of the roller.

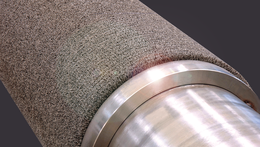

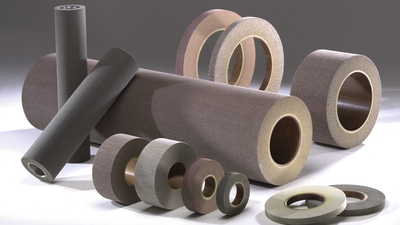

Non-woven Rolls

Neutral Mill Rolls are general-purpose, non-woven roll coverings used for primary metal and original equipment manufacturer (OEM) stamping operations. The rolls are constructed to be compressible to provide consistent, continuous contact for uniform wringing action. This reduces the need for additional drying, in turn reducing costs. When compared to rubber or urethane rolls, non-woven rolls have a significantly greater coefficient of friction to reduce metal coil spillage.

Compared to felt wipes, rubber or cork, Neutral Non-woven rolls offer longer life, better cleaning, "scrubbing" and wiping action, easier operation and the best value.

Non-woven Abrasive rolls

By varying abrasive content and construction, we are able to produce a wide range of roller options. Expertly matching grit and synthetic fiber grades create an open, flexible structure. The material is self-dressing and suitable for wet and dry processes. New abrasive particles are continually exposed to the surface for a consistent and uniform finish. An absolutely uniform fine final grind and a corresponding homogeneous surface finish can be achieved with the unique web construction. With the correct contact pressure, the flexible roller web adapts to surface offsetting and slight surface irregularity.

Specially designed engineered rolls eliminate costly surface contamination. These long-lasting rolls shed contaminants before they can damage the sheet's surface.

Custom Solutions

Osborn roller brushes are available in a variety of sizes with Osborn-developed treatments specific to your needs. Please ask our application engineer for the optimized set-up and operation parameters for your application.

Osborn experts are ready to speak with you.