Polishing Tools & Compounds

Airway Bias Sisal Buff (BS)

A compact buff, purely made of sisal web. It is a hard, aggressive tool. Sisal is a natural material, perfect for the polishing process due its excellent compound retention properties.

Airway Open Double Cloth Bias Sisal (ODCBS)

A flexible and economical cutting tool with irregular folds of sandwiched sisal and cotton cloth quilted together. The quilting of the cloth and sisal provides flexibility in the buffing of contoured parts, and enables the buff to effectively hold compound. These buffs can produce an aggressive cut or color finish and adapt well to any surface.

Airway Open Bias Sisal Buff (OBS)

A flexible and economical cutting tool with irregular folds of sandwiched sisal. These buffs offer a heavy cutting action with the flexibility to use on flat or contoured surfaces.

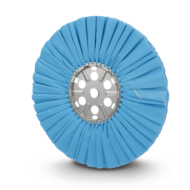

Airway Cotton Buff

Made from the tightest quality cloth specifications, these cloth buffs set the industry standard for quality and performance. The standard ventilated buff is suitable for almost every step in the polishing process. This buff runs cooler than stitched buffs, is more flexible and does a better job on contour work. The irregular folds fixed to a metal clinch ring form a flexible and economical buff.

Airway Mill Treated Cotton Buff

This type of buff is constructed using the highest quality material and is biased to reduce fraying and increase life. This makes them effective finishing tools for ferrous & non-ferrous metals, marble, plastics, and other materials. Mill treated buffs offer a firmer hand and can provide a one step cut and color process.

Airway Mill Treated Polycotton Buff

This type of buff is constructed using the highest quality material and is biased to reduce fraying and increase life . The steel center and rigid construction allow for greater pressure and faster cutting speed. Mill treated polycotton buffs offer a heavier, more flexible and resilient cut & color option.

Airway Polycotton Buff

Similar to the standard ventilated buffs this buff is flexible and versatile. This type of buff is constructed using the highest quality polycottons and is biased to reduce fraying and increase life. Various qualities of gray cloth can be selected depending on the results required. The irregular folds fixed to a metal clinch ring form a dense and economical buff for coloring.

Airway MagnaFlex™ Non-Woven Buff

Osborn developed a revolutionary buffing material that possesses characteristics never achieved with other buff cloths. The MagnaFlex™ material is primarily suited for mush buffing of non-ferrous metals without sharp edges. This cloth provides flexibility and can fold into parts with deep contours providing contact to create high color finishing. Designed to run at lower speeds and still provide cutting and coloring actions on part surfaces this buff will provide a clean result.

Diamond Cut Contact Wheel

This wheel is used with coated abrasive sanding belt operations as the carrier of abrasive belts and does not touch the product. Made from rubber sections versus cloth makes this contact wheel a durable and cooler wheel to carry belts. Pressed discs are provided to protect sections, maintain structure, providing firmness and keeping the edges from breaking down. The material allows flexibility when needed for contoured edges and parts as they pass across the abrasive belt surface. Used in automated and manual polishing coated abrasive belting applications. The contact wheel is available in multiple configurations and densities.

Conventional Cotton Buff

These buffs are made with 100% cotton. Loose full disc buffs are made with 1 row of sewing around the arbor hole. They are soft and flexible and are ideal for reaching uneven surfaces while buffing or coloring metals, hard rubber, marble and plastics. Spiral and concentric sewn buffs are harder than loose buffs.

Conventional Sisal and Cloth/Sisal Buff

Full disc sisal buffs are used for cut down operations of ferrous and non-ferrous metals. They are constructed from top quality sisal, sewn and treated for added cut and life. Cloth/Sisal conventional buffs alternate cloth and sisal ply to create the desired firmness of the buff. The use of the cloth in the buff adds value in compound retention and softens the buff for contoured parts. The combination of cloth and sisal provides cutting action and high color on steel and aluminum parts.

Airway Cloth Finger Buff

Used for cutting down operations. A very firm aggressive buff used where the surfaces vary in contour, or irregular shaped parts. Designed with folded and sewn fingers to get into those hard to reach spots.

Products for every application.

Osborn has the broadest selection of buffs, compounds and chemicals in the industry. Osborn will develop custom solutions for particular applications when standard products cannot meet the demands.

There is no one size fits all, Osborn prides itself on recommending the best, most efficient solution for every application. Our experts are happy to advise you.

Leading combination.

The combination of long-lasting Osborn buffs and economical compounds provides excellent results and fewer rejects. From woods and plastics to stainless steel, aluminum, titanium, or composites. Compounds and buffs are paired to provide a perfect combination.

Sisal Buffs

Sisal is a natural material, perfect for the polishing process due to its excellent compound retention properties. Sisal buffs are aggressive and usually follow a coated abrasive grinding process.

- Waved Sisal Cloth Buff

- Meter Sisal cloth Buff

- ODCBS Sisal Cloth buff

- Bias Sisal Buff

- OBS Sisal Buff

Cloth Buffs

An extensive range of different cloths in natural or mill-treated form has been developed to meet the demands of the polishing industry.

- Waved Cloth Buff

- Pleated Cloth buff

- Airway Cloth Buff

- Cloth Conventional

Abrasive Non-Wovens

Abrasive non-wovens consist of tangled nylon and/or polyester web with different types of abrasive grit particles resin bonded to the fibers. The material has an open and flexible structure, as it wears new abrasive is exposed to create a uniform and consistent finish, whether on a flat or slightly profiled surface. Abrasive grit particles are usually Silicon Carbide or Aluminum Oxide. The material can be used in both wet and dry operations.

- Non-Woven Convolute Wheel

- Non-Woven Flap Wheel

- Non-Woven Wide Face Wheel

- Waved Non-Woven Buff

- Airway Non-Woven Buff

- Rolls, Discs, and Hand pads

Coated Abrasives

Osborn offers a range of coated abrasive tools, making the most of the best materials on the market and our manufacturing expertise.

- Epoxy Flap Wheel

- Mechanical Flap Wheels

- Specialty Abrasives

Accessories & Treatments

Metal Centerplates, Nylon, and Aluminum accessories can be used to reduce the inside diameter of Buffs. Osborn cloths are often mill treated (at source) according to our specific demands, to make them stiffer or more flexible, longer wearing, or to perfectly suit the Osborn polishing compounds. Alternatively, finished buffs made from cloth or combinations of cloth and sisal web, are dip-treated for extended service life, greater hardness, or flexibility. Check out the various options

- Centerplates and Flanges

- Interchangeable Metal Adapters

- Mandrill

- Dip Treatments

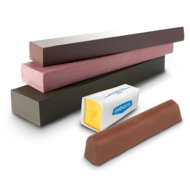

Liquid Compounds

Our liquid compounds are the most stable in the business due to their unique methods of manufacturing. Our compounds are made using the highest quality minerals, sized within a very limited range, to ensure no unexpected lines or scratches on a given surface. They adhere perfectly to Osborn buffs for a clean and economical process. Let our experts show you how to achieve the lowest cost per part!

- Solid Polishing Compounds

- Liquid Polishing Compounds

- Special Animal-Fat-Free Liquid and Solid Compounds

Solid Polishing Compounds

A full range of solid polishing compounds that can be used individually or in combination to achieve the desired result. All compounds can be supplied as sized robotic bars. For manual operations, Osborn offers approx. 1200g bags or bars.