Heavy Equipment

Explore Osborn's durable and efficient solutions tailored for the heavy equipment industry, ensuring peak performance and reliability for your toughest tasks.

Our Commitment to the Heavy Equipment Industry

At Osborn, we provide not just high-quality tools, but also expert guidance and a commitment to helping you achieve optimal results. Osborn is a reliable partner for businesses seeking to improve their surface finishing, cleaning, and other industrial processes.

Customer Collaboration

Our experts are experienced in surface treatment solutions and finishing tools, ready to partner with customers on how best to achieve optimum results.

Wide Range of Products

We offer a wide range of products specific to metal finishing in heavy equipment.

North American Manufacturing for Quality and Availability

Our manufacturing facilities across the United States and Mexico ensure the highest quality in the market.

Broadly Available Through Our Distributor Partners

Our complete product line is available and sold through our distribution partners.

Explore the cutting-edge solutions we offer for the Heavy Equipment industry. Our comprehensive brochure provides detailed information on our innovative products and services tailored to meet the unique demands of these sectors. Download our brochure today to discover how Osborn can help enhance your heavy equipment projects with high-quality, reliable solutions.

Our Solutions

ATB™ Wheel Brushes

- Osborn ATB™ Wheel Brushes are commonly used in the heavy equipment industry for deburring and rounding sharp edges on metal components, such as gears and engine parts, ensuring safer handling and improved assembly quality.

- These brushes provide a consistent surface finish, smoothing out rough surfaces and preparing components for further treatment or coating. This helps improve the overall durability and aesthetic appearance of heavy equipment parts.

- Osborn ATB™ Wheel Brushes are also utilized for cleaning and rust removal, effectively stripping away contaminants from surfaces like metal housings and frames. This process is crucial for maintaining the integrity and longevity of heavy equipment.

ATB™ Disc Brushes

- Osborn ATB™ Disc Brushes are ideal for deburring complex shapes and intricate geometries in heavy equipment components, such as gears and machined parts. Their design allows for precise edge blending and the removal of burrs in hard-to-reach areas, enhancing part quality and safety.

- These brushes are used for surface conditioning, providing a uniform finish on metal surfaces. They help remove oxidation, scale, and other surface imperfections, preparing components for subsequent processes like painting or coating.

- Osborn ATB™ Disc Brushes are effective in cleaning and preparing surfaces for bonding or assembly. They remove contaminants, oils, and residues, ensuring that the surfaces are clean and ready for optimal adhesion and assembly.

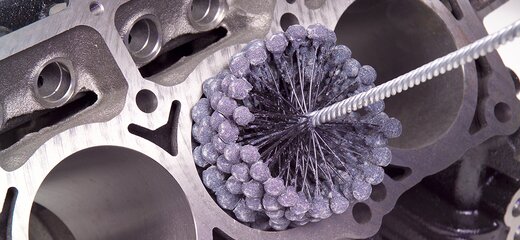

ATB™ NovoFlex Honing Tools

- Osborn ATB™ NovoFlex Honing Tools are used for precision honing of cylinder walls and other critical components in heavy equipment. They provide a consistent and accurate finish, ensuring optimal fit and function of parts like engine cylinders and hydraulic components.

- These honing tools achieve a superior surface finish, enhancing the performance and efficiency of heavy equipment. By creating a crosshatch pattern, they improve oil retention on surfaces, reducing friction and wear during operation.

- Osborn ATB™ Novoflex Honing Tools are also used to deburr and smooth interior surfaces, removing minor imperfections and burrs. This ensures the reliability and longevity of components by preventing potential damage or wear caused by rough edges.

Stringer Bead Wheel Brushes

- Osborn Stringer Bead Wheel Brushes are specifically designed for cleaning weld seams in heavy equipment. They efficiently remove slag, spatter, and oxides from weld beads, ensuring a clean and smooth finish that enhances both the appearance and structural integrity of the weld.

- These brushes are ideal for surface preparation before painting or coating, particularly on weld joints and edges. They help remove rust, scale, and other contaminants, providing a clean surface that improves adhesion and prolongs the life of coatings.

- In addition to weld cleaning, Osborn Stringer Bead Wheel Brushes are used to remove corrosion from metal surfaces. This is crucial in maintaining the longevity and safety of heavy equipment, as it prevents further deterioration and prepares the surface for protective treatments.

Cup Brushes

- Osborn Cup Brushes are widely used in the heavy equipment industry for removing rust, old paint, and other surface contaminants from large metal surfaces. This process is essential for preparing equipment for repainting or refurbishing, ensuring a clean base for new coatings.

- These brushes are ideal for cleaning and preparing surfaces before welding or assembly. They efficiently strip away dirt, grease, and debris, providing a smooth and clean surface that enhances the quality of welds and the overall integrity of assembled parts.

- Osborn Cup Brushes are also used for cleaning weld seams and blending welded areas with the surrounding metal. They remove slag and spatter from welds, resulting in a smooth, polished finish that improves the appearance and strength of welded joints in heavy equipment.

End Brushes

- Osborn End Brushes are essential for cleaning and finishing in tight or hard-to-reach areas of heavy equipment, such as keyways, threaded holes, and corners. Their small, concentrated design allows for detailed work that larger brushes can't achieve.

- These brushes are effective for deburring and blending sharp edges on metal components. They help smooth out rough surfaces and remove burrs, ensuring that parts are safe to handle and properly fit together during assembly.

- Osborn End Brushes are used to prepare surfaces for welding or coating by removing rust, paint, and other contaminants. This preparation is crucial for achieving strong welds and ensuring that coatings adhere properly, thereby enhancing the durability and appearance of the equipment.

Heavy Equipment

Products.

ATB Uni-Lok® Turbo Disc Brush

Osborn’s ATB Uni-Lok® Turbo Disc Brush features Round Crimped abrasive filaments in a unique turbo design to effectively tackle moderate to severe burrs or tasks where conformability is required. When used in dry applications, turbo design draws air into the brush face to run cooler. When used in wet applications, the turbo design allows more coolant to flow within the brushing surface.

ATB Uni-Lok® Quick Change Brush

Osborn’s ATB Uni-Lok® Quick Change Brushes feature a permanently mounted ¼” shank for quick, convenient attachment to CNC machines, automatic equipment, portable tools, and robotic cells. These small diameter brushes feature premium-quality nylon filament with choice of Round Crimped Silicon Carbide or Round Ceramic abrasive to serve a variety of deburring needs. The unique composite design allows for “touching” of surrounding raised surfaces without harming the part or the brush. Designed and tested for longevity and uniformity.

ATB™ Miniature Wheel Brush

Versatile Osborn ATB™ Miniature Wheel Brushes are designed for uniform performance even when used on extremely hard materials. Each nylon filament is impregnated with choice of tough abrasive for precision ultra-fine deburring and edge contouring.

Novoflex - Small Diameter

Osborn’s small diameter ATB™ Novoflex Tools are designed with round, abrasive beads fastened to the end of flexible nylon filaments sized to address smaller applications such as brake cylinders, hydraulics and valve guides. This self-centering tool will conform to the bore surface to provide a consistent, even surface finish over the life of the tool.

Novoflex - Standard Duty

Designed with round, abrasive beads fastened to the end of flexible nylon filaments, Osborn ATB™ Novoflex flexible honing tools are ideal for a variety of bore cleaning tasks. Tools create crosshatch pattern for improved oil retention and increased efficiency, and will even provide an edge break not possible with conventional honing stones.

Novoflex - Heavy Duty

The longer brush length of Osborn’s heavy duty ATB™ Novoflex Tool tackles tough honing projects with efficiency. Silicon Carbide abrasive beads are fastened to durable nylon filaments to allow the tool to conform to the bore surface. Flexible filaments are engineered to provide the correct pressure to create an ideal hone over the life of the tool.

ATB Monarch™ Wheel Brush

The highly versatile Osborn ATB Monarch™ Wheel Brush features premium Round Crimped nylon filaments with abrasive Silicon Carbide. Brush is narrow-faced with long trim, making it ideal for confined areas and irregular shapes. Quality materials and construction provides aggressive cutting power without sacrificing longevity.

TY™ Encapsulated Cup Brush - Standard Duty

Osborn’s TY™ Encapsulated Cup Brush is constructed with proprietary TufWire™ with a specially formulated polymer that supports wire strands, resulting in maximum performance with minimum pressure.

ATB™ Diamond Superabrasive Wheel Brush

Designed to provide uniform, repeatable results, Osborn ATB™ Diamond Superabrasive Wheel Brushes offer superior performance for a variety of polishing, deburring, and edge honing applications. Brushes are engineered for optimal edge honing of super hard materials such as CBN, ceramics, diamond, and glass without sacrificing brush life. ATB™ Diamond Superabrasives lower process costs and create a cleaner, more efficient production environment by minimizing or eliminating the secondary cleanup operation.

ATB Uni-Lok® Bridle

Improve the aggressiveness of Osborn’s ATB™ Composite brushes with ATB Uni-Lok® Bridles. Sold in three packs, these Bridles are designed to significantly reduce the flare of filaments to increase rigidity for use on heavy-duty applications. Not for use on ATB™ turbo discs.