ATB®

ATB® is the abbreviation for Advanced Technology Brush System and forms our product range of brushes for automated deburring directly after the machining process.

ATB® - High-tech brushes for automated deburring.

ATB® brushes are precision tools that are largely responsible for the quality of the end products. They can be matched component-oriented to almost any material to be processed.

Our ATB® brushes are available with a wide range of abrasive bristles and wire trim in different grit sizes and filament/wire diameters.

ATB® brushes are designed for direct adaptation to tool holders, which means that they can be used in machining centers, CNC lathes & milling machines, robot cells, etc. The use of the brushes takes place downstream of the machining process.

The brushes are used downstream of the machining process and can be used with cooling lubricants, emulsions, or water without any problems.

water. This means that the machined workpieces can be deburred and finished directly, reliably, and reproducibly on the machine without reclamping.

Before/after comparison.

Before machining - clear burr formation on the edge. Milling grooves on the surface.

After machining - burrs were reliably removed and the edges rounded. The surface has an even, brushed look.

Advantages and

Application examples.

ATB® brushes have a 4 x higher fill density than the disc brushes produced in the conventional process (punched). As a result, the service life of the brushes is increased many times over, with higher throughput speeds and better and more efficient deburring results.

- Minimal process costs

- Firmly encapsulated abrasive bristles

- Extremely dense fill surface

- Enormously long tool life

- High dimensional stability and concentricity

- Use of cooling lubricant, emulsions, and water possible

- Plane fill surface

- Numerous, different fill materials e.g. abrasive bristles, wire materials, mixed fill material

- No reclamping of the workpiece after machining

Due to shorter machining times and very uniform edge rounding, our ATB® brushes are particularly suitable for deburring:

- Milled and turned parts

- Ground parts

- Sintered parts

- Stamped, nippled, and pressed parts

- Pneumatic and hydraulic parts

- Engine components, e.g. cylinder head, cylinder block, etc.

- Die-cast parts

- Valve plates

- Flat ground parts

- Toothed components

- Contact and sealing surfaces

- Finishing

Osborn

ATB® portfolio.

Tool holders & adaptability.

ATB® brushes are compatible with the following tool holders for direct adaptability for use in automated machining stations:

ATB®-Disc brushes

- Shell mill adaptors DIN 69882-3 / Universal arbors DIN 69882-2

- Planet head holder

- With Osborn clamping sets, other holders are possible such as Weldon holders or similar.

- Toolholders with HSK-taper shank DIN 69893

- ISO Taper-toolholders SK nach DIN 69871

- Holders for straight shank tools DIN 69882-4 (Weldon DIN 1835 B) etc.

ATB®-Wheel brushes

- Shell mill adaptors DIN 69882-3 / Universal arbors DIN 69882-2

- Through hole with and without keyway

- With Osborn clamping sets (shank holders)

- Toolholders with HSK-taper shank DIN 69893

- ISO Taper-toolholders SK nach DIN 69871

ATB®-End brushes

- shank holders

- Toolholders with HSK-taper shank DIN 69893

- ISO Taper-toolholders SK nach DIN 69871

- Holders for straight shank tools DIN 69882-4 (Weldon DIN 1835 B) etc.

Trim patterns & designs.

In order to achieve the best possible deburring and finishing results, different fill patterns and designs are required. Depending on the available product families of ATB® brushes, we offer the following fill types, among others:

ATB® disc brush

- full fill (max. fill density)

- partial fill (segmented)

- turboshape

- ring fill

- tapered/angled fill (under angle)

- spotted version

ATB® wheel brush

- full fill (max. fill density)

- partial fill (segmented)

ATB® End Brush

- full fill (max. fill density)

Determined by the material to be processed and the workpiece geometry, ATB® brushes can be equipped with various fill materials, from wire fill to abrasive bristles to mixed fill.

Technical feasibility & standard configurations.

In order to make the best possible use of the advantages of our ATB® product line, it is often necessary to exchange ideas with our product professionals. Often, application-specific brushing tools are worked out for the customer, which is developed taking into account the entire machining process.

We offer the following standard configurations (dimensions) for the three ATB® product families:

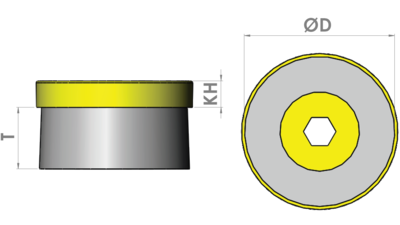

ATB® Disc brush

- Outer-Ø D: Ø40 to Ø250 mm

- Trim height T: 35 mm

- Body height KH: 13 mm

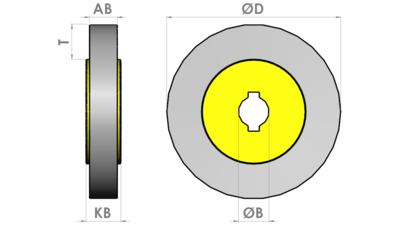

ATB® Wheel Brush

- Outer-Ø D: Ø100 to Ø355 mm

- Working width AB: 6 to 36 mm

- Body width KB: 10 to 40 mm

- Mounting hole ØB: 16 to 134 mm with and without keyways

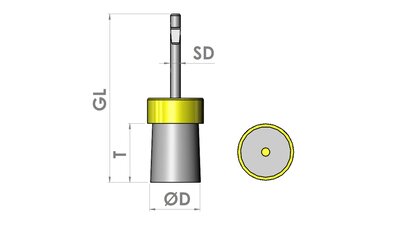

ATB® End Brush

- Outer-Ø D: Ø16 to Ø40 mm

- Trim height T: 25 to 30 mm

- Shaft diameter: 6-8 mm

- Total length SL: 85 to 176 mm

ATB®

Products.

ATB Uni-Lok® Tuftmatic Disc Brush

Constructed with a durable polypropylene base and a dense configuration of strategically located tufts, Osborn ATB Uni-Lok® Tuftmatic™ Disc Brushes offer thorough, uniform performance in both dry and wet applications. Each tuft features high-quality nylon filaments impregnated with Silicon Carbide, and is configured to allow abrasive filaments to flow evenly and consistently over the most intricate flat-faced parts. Compatible with Osborn’s Uni-Lok® adapter system and designed for maximum effectiveness.

ATB Uni-Lok® Turbo Disc Brush

Osborn’s ATB Uni-Lok® Turbo Disc Brush features Round Crimped abrasive filaments in a unique turbo design to effectively tackle moderate to severe burrs or tasks where conformability is required. When used in dry applications, turbo design draws air into the brush face to run cooler. When used in wet applications, the turbo design allows more coolant to flow within the brushing surface.

ATB Uni-Lok® Quick Change Brush

Osborn’s ATB Uni-Lok® Quick Change Brushes feature a permanently mounted ¼” shank for quick, convenient attachment to CNC machines, automatic equipment, portable tools, and robotic cells. These small diameter brushes feature premium-quality nylon filament with choice of Round Crimped Silicon Carbide or Round Ceramic abrasive to serve a variety of deburring needs. The unique composite design allows for “touching” of surrounding raised surfaces without harming the part or the brush. Designed and tested for longevity and uniformity.

ATB™ Microabrasive Internal Brush

Premium high-performance nylon filaments with choice of embedded abrasives offer ultra-fine deburring and cleaning of holes produced by micro drilling. Designed for uniform brushing action that will not alter the hole diameter or surface finish. Can be used manually or on power tools. Constructed for longevity and use on applications requiring absolute precision. Note: brush selected should be ~0.015 inches larger than hole.

ATB™ Tube Brush

Featuring spiral-mounted nylon filaments with abrasive Silicon Carbide grit, Osborn ATB™ Tube Brushes offer extra cutting and cleaning action without sacrificing brush life. Brush can be mounted onto a portable or stationary tool for efficient operation.

ATB™ Miniature Wheel Brush

Versatile Osborn ATB™ Miniature Wheel Brushes are designed for uniform performance even when used on extremely hard materials. Each nylon filament is impregnated with choice of tough abrasive for precision ultra-fine deburring and edge contouring.

ATB™ Miniature End Brush

Osborn ATB™ Miniature End Brushes feature a small diameter for light duty cleaning, deburring, and surface finishing tasks. Brushes are constructed with premium nylon filaments with choice of Aluminum Oxide or Alumina Silicate abrasive.

ATB Monarch™ Wheel Brush

The highly versatile Osborn ATB Monarch™ Wheel Brush features premium Round Crimped nylon filaments with abrasive Silicon Carbide. Brush is narrow-faced with long trim, making it ideal for confined areas and irregular shapes. Quality materials and construction provides aggressive cutting power without sacrificing longevity.

ATB™ End Brush

Small diameter brush featuring high-performing abrasive nylon filament to quickly and efficiently clean and finish inside diameters, spot facing, and recessed areas. Precision design makes these brushes ideal for operations where balance is critical, as in CNC and robotic use. Attached ¼” stem also allows for use on portable air and electric tools.

ATB™ Cup Brush - Flat Trim

Featuring a precision cut flat trim and premium quality 0.045" x 0.090" rectangular nylon filaments, this Osborn ATB™ Cup Brush is ideal for flat surface finishing and deburring. Brushes are heavily filled with filaments impregnated with choice of Silicon Carbide or Aluminum Oxide and are designed for maximum longevity. Note: 4" brushes include premium quality bridle for maximum filament rigidity.