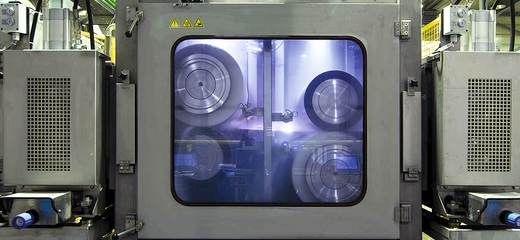

Rolling Mills

Osborn offers different types of roller brushes for the manufacturing processes of sheet and strip in steel and rolling mills.

Fill Materials.

Types and Usage.

Synthetic Monofilaments - Non Abrasive, Standard Types

| Novofil | NN | NM | NH | HR | PR |

|---|---|---|---|---|---|

| Temperature resistance | |||||

| Permanent (°C) | 90 | 95 | 95 | 90 | 70 |

| Max. short-term (°C) | 120 | 130 | 120 | 120 | 100 |

| Mechanical properties | |||||

| Bend recovery | ✔ ✔ | ✔ ✔ | ✔ ✔ | ✔ ✔ | ✔ |

| Stiffness | ✘ | ✔ ✔ | ✔ ✔ | ✔ | ✔ |

| Resistance to abrasion | ✔ ✔ | ✔ ✔ | ✔ ✔ | ✔ ✔ | ✔ |

| Chemical resistance | |||||

| Against alkalines | ✔ | ✔ ✔ | ✔ ✔ | ✔ ✔ | ✔ ✔ |

| Against acids | ✘ | ✘ | ✔ | ✘ | ✔ ✔ |

✔ ✔: Excellent; ✔: Good; ✘: Not suitable

Synthetic Monofilaments - Abrasive, Standard Types

| Novofil | NH-S | NH-A | NN-S | NN-A | HR-S | HR-A |

|---|---|---|---|---|---|---|

| Abrasive Material | SiC | Al2O3 | SiC | Al2O3 | SiC | Al2O3 |

| Grit Size | 46-1000 | 80-1000 | 46-500 | 60-500 | 180-320 | 180-320 |

| Temperature resistance | ||||||

| Permanent (°C) | 95 | 95 | 90 | 90 | 95 | 95 |

| Max. short-term (°C) | 120 | 120 | 120 | 120 | 130 | 130 |

| Mechanical properties | ||||||

| Bend recovery | ✔ ✔ | ✔ ✔ | ✔ | ✔ | ✔ ✔ | ✔ ✔ |

| Stiffness | ✔ ✔ | ✔ ✔ | ✔ | ✔ | ✔ ✔ | ✔ ✔ |

| Resistance to abrasion | ✔ ✔ | ✔ ✔ | ✔ | ✔ | ✔ ✔ | ✔ ✔ |

| Chemical resistance | ||||||

| Against alkalines | ✔ ✔ | ✔ ✔ | ✔ | ✔ | ✔ ✔ | ✔ ✔ |

| Against acids | ✔ | ✔ | ✘ | ✘ | ✘ | ✘ |

✔ ✔: Excellent; ✔: Good; ✘: Not suitable

Crimped Metal Wires, Standard Types

| Wire | Steel | Stainless Steel | Brass | Phosphor-Bronze | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Carbon steel | AB steel (alloyed) |

Bessemer soft steel |

Brass coated | Cord wire brass coated |

1.4310 |

Highly noncorrosive 1.4401, 1.4571 |

Highly heatresistant | |||

| Temperature resistance | ||||||||||

| Permanent (°C) | 300 | 300 | 250 | 300 | 300 | 400 | 500 | 500-1250 | 170 | 170 |

| Wear properties | ||||||||||

| Tensile strength (N/mm2) | 1900-2100 | 2400-2700 | 700-1200 | 2300 | 1900-2300 | 1700-1900 | 1700-1800 | 1600 | 900 | 1000-1300 |

| Fatigue resistance | ✔ | ✔ ✔ | ✘ | ✔ ✔ | ✔ ✔ | ✔ ✔ | ✔ | ✔ | ✘ | ✔ |

| Erosion performance | ✔ | ✔ ✔ | ✘ | ✔ ✔ | ✔ ✔ | ✔ | ✘ | ✔ | ✘ | ✘ |

✔ ✔: Excellent; ✔: Good; ✘: Not suitable

Micro-Fibre Multifilament

| Novofil | MY | MY-A | MY-S | MX |

|---|---|---|---|---|

| Material group | not abrasive | abrasive | abrasive | Filament mixture |

| Abrasive material | Al2O3 | SiC | SiC/Al2O3 | |

| Properties |

|

|||

Natural Fibre and Animal Hair

| Filament | Horse Hair | Tampico |

|---|---|---|

| Material Group | Animal Hair | Natural Fibre |

| Properties |

|

|

Our Services in Burgwald.

Through many years of cooperative development work with machinery manufacturers in the design of rolls and brushing machines as well as with the operators concerning production line and process optimization, we achieved wealth of experience in this field. Through our worldwide sales and service network we are able to guarantee comprehensive technical support for new production lines around the globe in all stages of project development from the initial design to commissioning.

A whole list of well-known manufacturers in the business of strip and heat treatment plants and rolling mill technology benefits from this expertise, which ultimately rewards the plant operator in the form of highly engineered products, innovative technologies and cost effective solutions.

In addition to the manufacturing of complete brush rollers with different shafts and body constructions, our range of services also includes bearing units, splash rings and accessories. We also manufacture and supply shafts and complete systems for other roll types used in strip line systems. These come without or upon request, with hard chrome, polyurethane, rubber or other special coatings.

For Factory Assembly (FA) brush roll systems (Integrated maintenance service) we offer the following services:

- Brush roll re-filling and non-woven refurbishment

- Integrated maintenance service concepts

- Re-trimming and re-balancing of brush rolls

- Shafts and journal control and repairing

- Bearing control and exchange

- Shaft improvement/adaptation

- Shaft straightening

- Stress free annealing of shafts

- Replacement of end and balancing collars

- Replacement of fittings and accessories

- Transport and packaging concepts

- Supply of brush roll trimming equipment

Upon receipt by our service centre, each roller immediately undergoes a professional inspection in accordance to the agreed upon service contract. The condition as well as the time and expense involved with the maintenance are documented with the aid of standardised protocols. The longer the service life of rollers, the more important it is to have the proper condition of the bearings to avoid additional downtime or outages. For this reason, bearing units are checked and maintained by us. If necessary, the bearing unit or other accessories are renewed.

The quiet and low-vibration running of the rollers is important in order to avoid shatter marks or shading on the strip surface caused by the brush roller. Each shaft is checked for imbalance and concentricity deviation so that it can be straightened and rebalanced if necessary. Worn bearing seats are welded and precisely re-machined to the original specification.

Following this, immediate re-brushing or assembly of prefabricated brush segments takes place.

Before - the filling is worn out and needs to be refilled

Step 1 - The used material gets completely removed and the roller is covered with new material

Step 2 - To achieve the best possible result, the brush surface is sheared and processed.

Step 3 - The brush is carefully aligned and precisely balanced to ensure optimal results.

Once all parameters have been checked, it is secured and packed for safe delivery back to the customer.